Extend the Life of Your Equipment Attachments

Category: Equipment and Solutions

If you are an experienced heavy equipment operator, you probably know your machine inside and out. In fact, you may have extensive knowledge of all the engines within your fleet.

However, it’s also necessary to understand your machine’s attachments and how to extend their life, as well as how to implement proper maintenance and storage conditions.

Tips on How to Prolong the Life of Construction Attachments

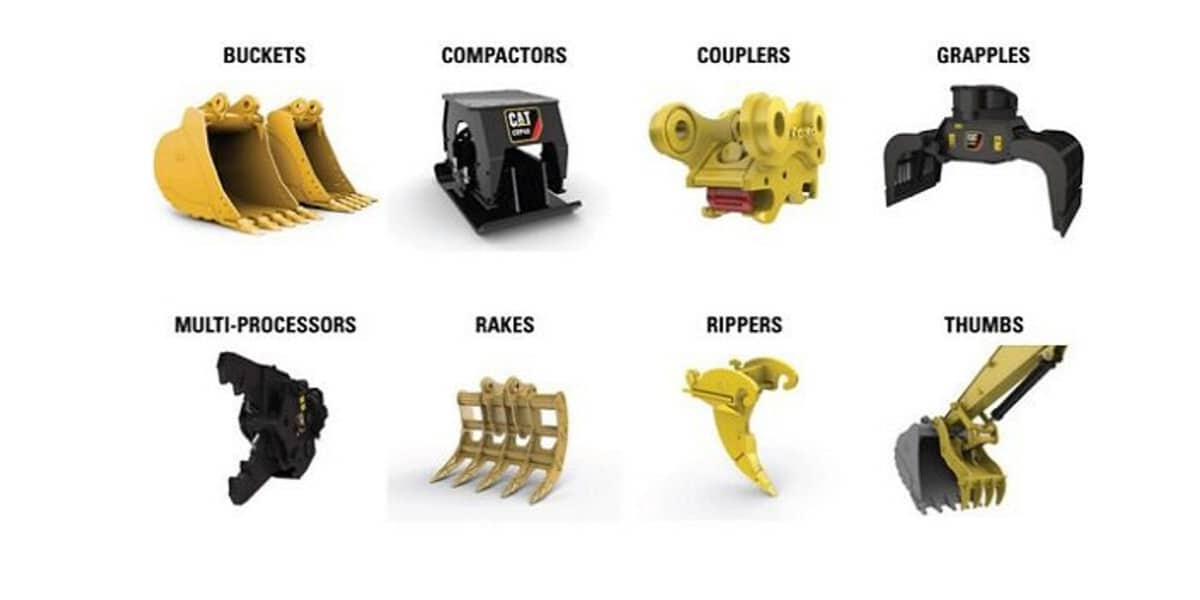

The No. 1 way to prolong the longevity of your heavy construction attachment is to determine the right type for each piece of machinery. You should consider factors such as climate, the condition of the jobsite and material composition. Specific attachments are for particular environments, machines and substances, so it’s vital to research which will best fit your application.

You never want to force attachments onto a piece of equipment that isn’t identified. Not only will it damage the attachment itself, but it will also harm the machine and decrease your efficiency and bottom line. It also comes down to being a safety issue and it can deplete the life of your equipment.

When you choose the correct attachment for each piece of machinery, you can prevent the need for extensive repairs or replacements. Tips on prolonging the lifespan of attachments include:

- Use attachment only within its operational perimeters

- Pay attention to hydraulic flows

- Wash and clean attachments after daily use

- Grease fittings to ensure proper lubrication

- Replace worn-out parts to keep attachment running under optimal conditions

- Swap out teeth and bolt-on edges of bucket

- Inspect loose sections and repair if necessary

- Refer to maintenance and operating manuals

Suitable Maintenance and Storage Techniques

Regular maintenance and inspection can reduce unwanted downtime, whether you’re taking care of your fleet or attachments. Daily inspection tasks performed by a machine operator is key to prevent future and more substantial problems. He or she knows the piece of equipment better than anyone else on the jobsite. However, an inspection should cover more than a walkaround glance.

Because construction equipment attachments require accurate connections to your machines, the attachment areas often experience high points of stress. Your daily checklist should include the following when looking at the exact add-on locations:

- Ensure shielding is in place by checking hoses and fittings for leaks and cracks

- Make sure fittings aren’t loose

- Clean hoses and fittings from contaminants

- Lubricate equipment’s critical parts

- Inspect locking mechanisms

The process is not time-consuming and can help your equipment in the end. Proper storage is another aspect in extending the life of your equipment attachments. In reality, it can be the biggest asset in increasing your ROI over an extended period. Refer to the following steps on how to prepare your attachments for storage and which environments are best:

- Clean attachment by removing grease, dirt and debris

- Inspect for visible damage, breaks and wear

- Order parts right away to make repairs and avoid delays

- Tighten hydraulic connections, loose nuts and cap screws

- Lubricate grease fillings

- Use grease to fill exposed areas of cylinder rods

- Protect hydraulic system from pollutants by connecting hydraulic couplers

- Touch up unpainted sections to prevent rust

- Replace decals if they are unreadable

- Store heavy equipment attachments in a protected and dry place

You always want to store heavy equipment and attachments in a sheltered location to protect them from various elements. Keep materials away from moisture and sunlight to reduce the risk of corrosion, rust and degradation.

When you refer to this quick guide, you can extend the life of your construction attachments.

NMC Cat Can Help With Your Attachment’s Life

Contact NMC experts online to learn about how we can help you extend the life of your heavy equipment attachments. You can also call us at 800-628-6025 to speak with a representative.