Cat® Cold Planers are designed for small paving jobs in residential and commercial applications and are primarily used to economically restore asphalt and concrete surfaces. They are ideal for milling imperfections prior to resurfacing, removing deteriorated pavement, removing traffic lane stripes and jobs where the use of dedicated planers is limited. The Cat Cold Planers are designed for use on Cat Skid Steer Loaders, Compact Track Loaders, Compact Wheel Loaders and Backhoe Loaders.

| Dimensions | |

| Working Width | 17.7 in |

| Maximum Cutting Depth | 5.9 in |

| Required Hydraulics | High Flow |

| Overall Width | 68.1 in |

| Overall Length | 46.6 in |

| Overall Height | 42.5 in |

| Weight | 1609.4 lb |

| Optimal Hydraulic Flow | 80-117 L/min (21-31 gpm) |

| Optimal Hydraulic Pressure | 160-240 bar (2320-3480 psi) |

| Drum Speed | 142-250 rpm |

| Optional Drum Widths/Depths | 80/200-450/150 mm (3/8-18/6 in) |

| Tilt Angle Range +/- | 8.5 degrees |

| Side Shift Travel | 25.6 in |

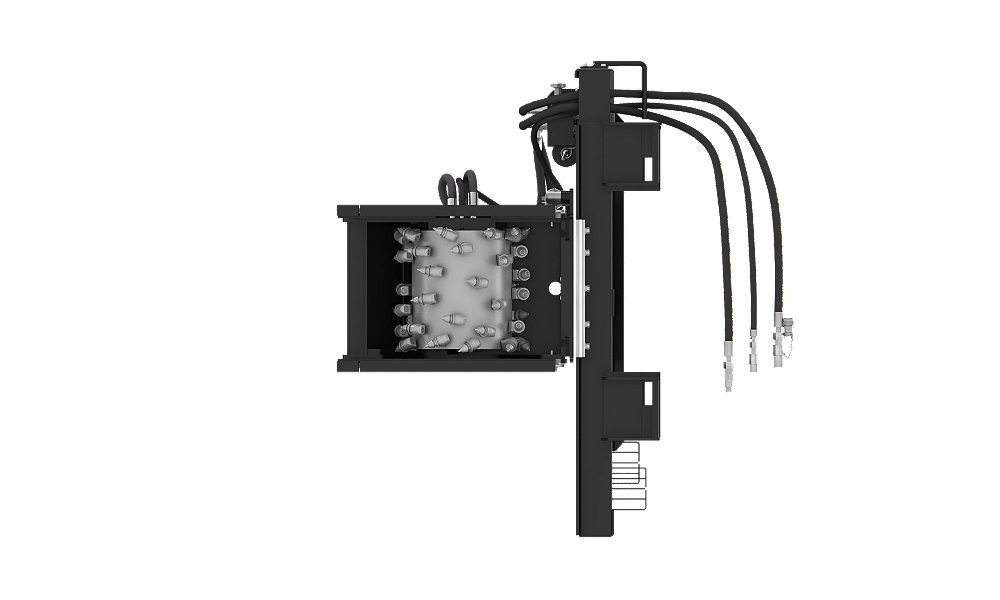

| Conical Bits | 42 |

| Standard Bit Type | All Purpose |

Application

Designed for small paving jobs in residential and commercial applications, and are primarily used to economically restore asphalt and concrete surfaces. Ideal for milling imperfections prior to resurfacing, removing deteriorated pavement, removing traffic lane stripes and jobs where the use of dedicated planers is limited.

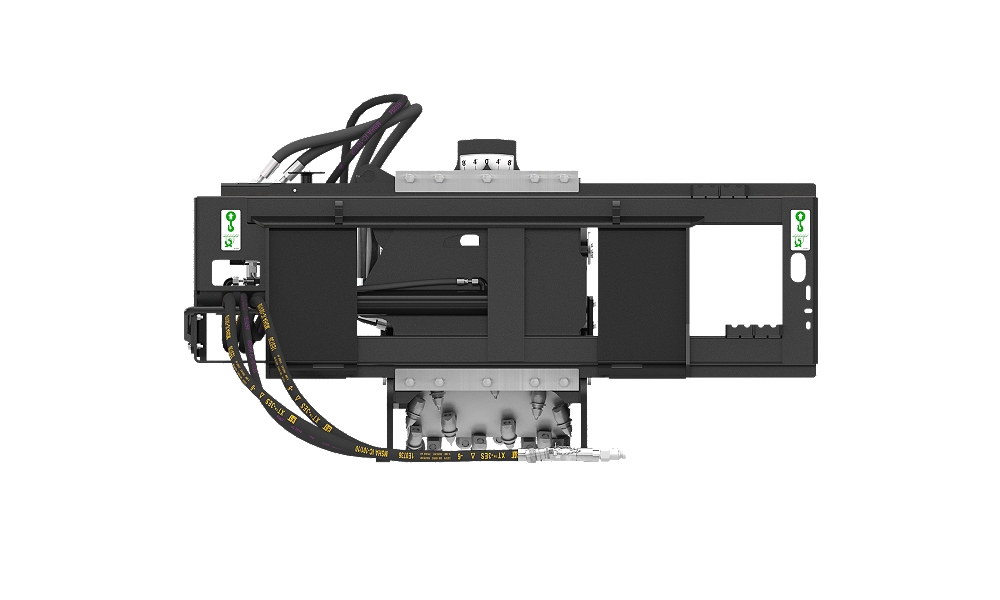

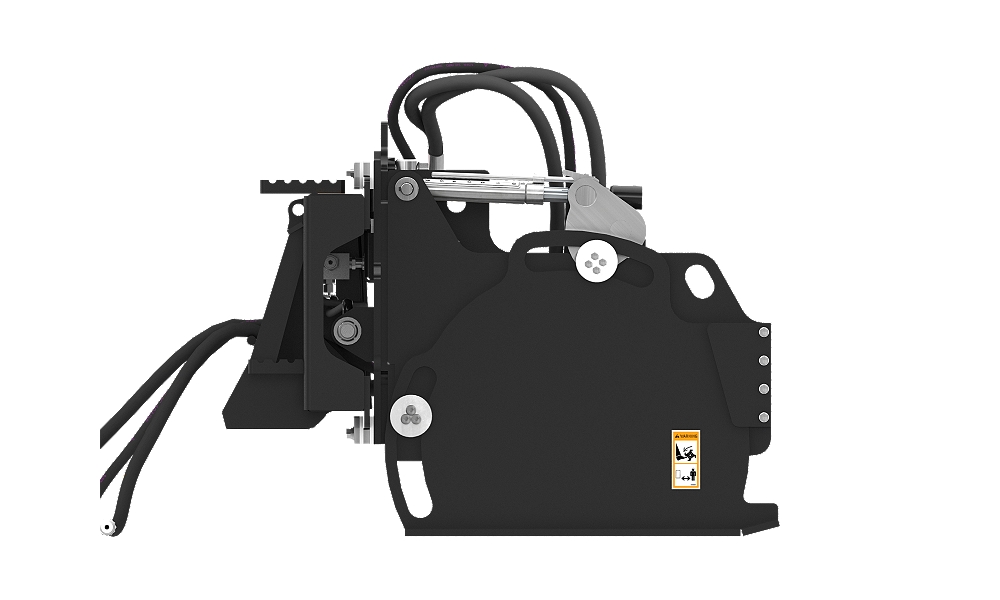

Self-leveling Design

Self-leveling design automatically levels itself when placed on the ground for consistent depth control without operator adjustments and excellent spoil retention.

Two Wear-Resistant Skid Plates

Two wear-resistant skid plates remain parallel to the ground for optimum stability.

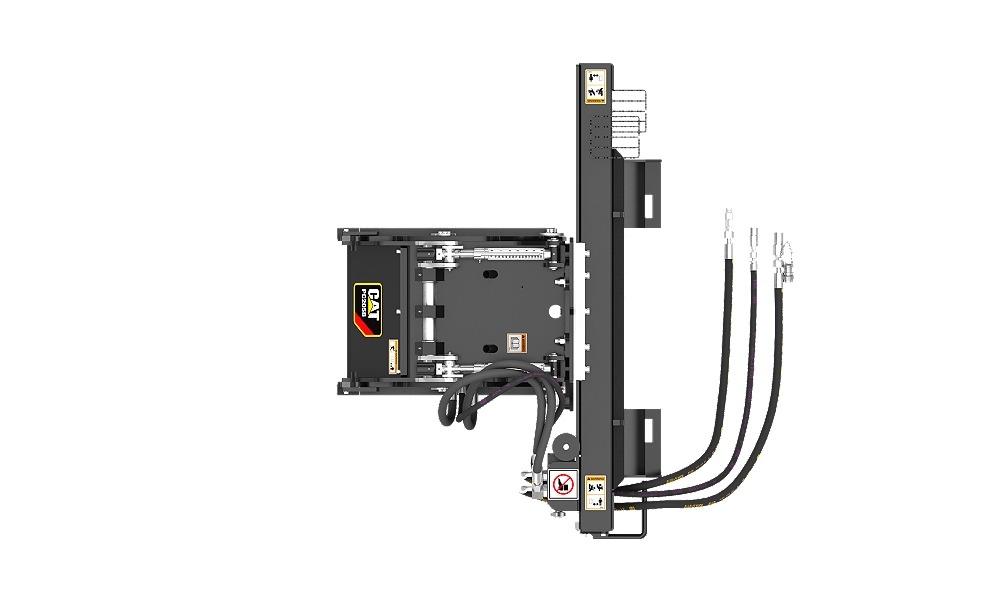

Hydraulic Sideshift

Hydraulic sideshift permits close planing to curbs, walls and other obstructions.

Independent Left/Right Depth Control

Independent left/right depth control allows maximum drum depths to be adjusted independently on each skid. Gauges are easily viewable from the cab. Independent depth control is mechanical on the PC104B and PC205B models; hydraulic independent depth control is standard on the PC305B-PC412B models.

Max Pro Pressure Gauge

Max Pro Pressure Gauge provides operator feedback to adjust speed for maximum productivity in changing material loads. Gauge displays planer performance in real-time conditions and is visible from the cab. Standard on XHP models.

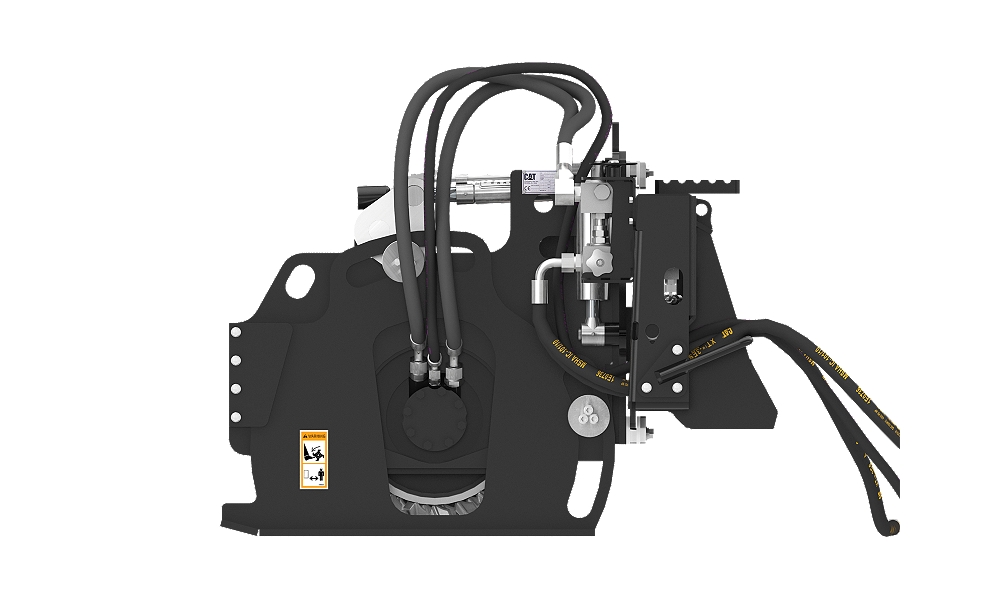

Direct Drive System

Direct drive system on the standard flow models features a variable speed, uni-directional, gerotor style hydraulic motor. Direct drive system on high flow and XHP models features a hydraulic radial piston motor to ensure maximum cutting rate and drum torque for optimal production performance and efficiency.

Float, Spring Tilt and Hydraulic Tilt

Float enables planers to follow the contour of the surface. Float is activated by a knob and is only available on high flow and XHP planers. Spring tilt and hydraulic tilt enable planers to oscillate for angled cuts. Tilt is hydraulically controlled on high flow models and spring controlled on standard flow planers.

Bits and Water Sprinkler

All Purpose concrete bits are standard. Optional concrete bits, extreme life bits and water sprinkler kits are available for all models.