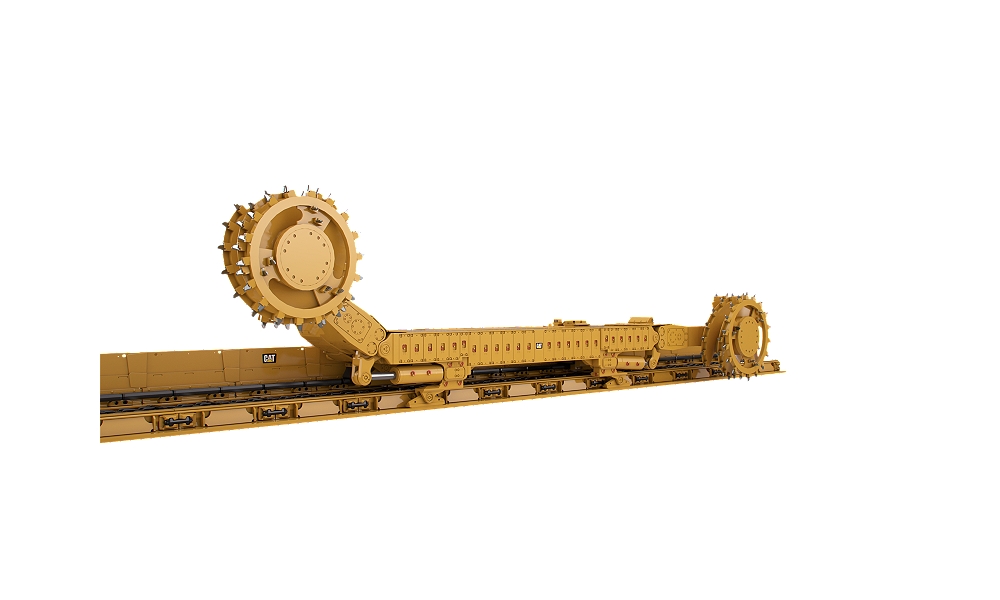

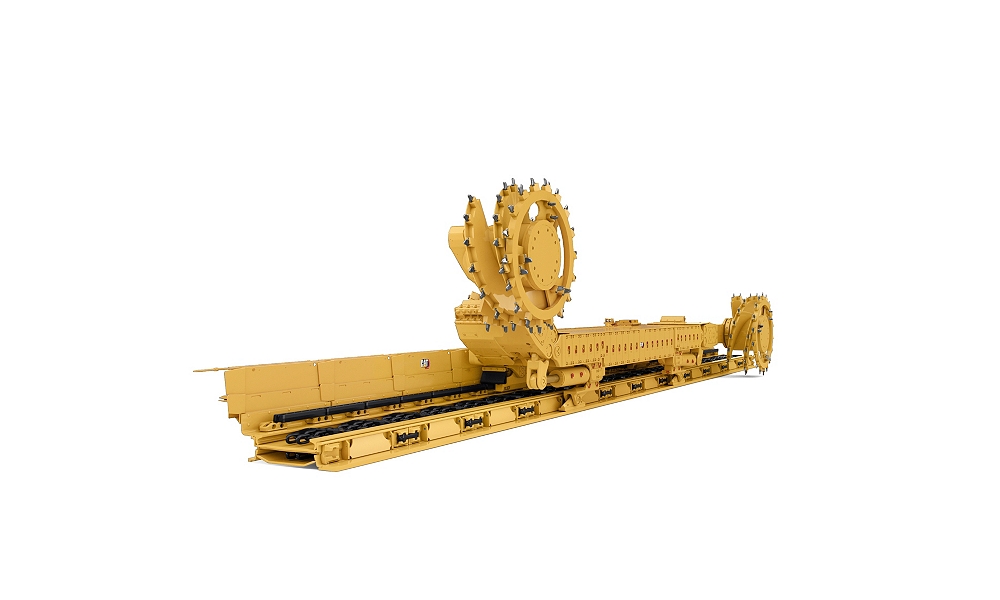

The EL2000 incorporates all the features and benefits that have been established with the Cat shearer range in a compact, rugged machine designed to meet the demands of high productivity in low- to medium-seam applications. The haulage system of the powerful EL2000 is tailored to the needs of high-productivity medium-seam applications with up to 125 kW (168 hp) AC drives.

| Specifications | |

| Seam Range | 1.8-4.5 m (71-177 in) |

| Haulage Power | 2 × 125 kW (2 × 168 hp) @ 50 Hz; 2 × 125 kW (2 × 168 hp) @ 60 Hz |

| Cutting Power | 2 × 500 kW (2 × 671 hp) @ 50 Hz; 2 × 600 kW (2 × 805 hp) @ 60 Hz |

| Haulage System | AC |

| Coal Sizer | 134 hp |

| Body Height | 20.5 in |

| Haulage Speed | Up to 32 m/min (Up to 105 ft/min) |

| Operating Voltage | 2300V, 3300V, 4160V |

| Installed Power | 2548 hp |

| Typical Machine Length | 45.1 ft |

| Applicable Minimum Pan Width | 40.6 in |

| Machine Weight - Approximate | 77 ton (US) |

| Pump Motor | 67 hp |

| Cutting Drum Diameter | 1.40-2.30 m (55-91 in) |

| Haulage Pull | Up to 920 kN/206,824 lbf (Up to 91 tonnes/100 tons) |

| Height Range | 1.80-4.50 m (71-177 in) |

| Available Haulage Motors | 2 × 125 kW (2 × 168 hp) |

| Machine @ 50 Hz | |

| Minimum Pan Width | 40.6 in |

| Haulage System | AC inverter drive |

| Installed Power | Up to 1780 kW (Up to 2,387 hp) |

| Seam Range | 1.8-4.5 m (71-177 in) |

| Available Cutting Power | 2 × 500 kW (2 × 671 hp); 2 × 620 kW (2 × 831 hp); 2 × 750 kW (2 × 1,006 hp) |

| Pump Motor | 40 hp |

| Cutting Drum Diameter | 1600-2500 mm (63-98.5 in) |

| Typical Machine Length - Drum Centers | 46.15 ft |

| Machine Weight - Approximate | 77 ton (US) |

| Operating Voltage | 3300 V |

| Haulage Power | 2 × 125 kW (2 × 168 hp) |

| Haulage Speed (maximum) - High Downdrives | 98.8 ft/min |

| Body Thickness | 24 in |

| Haulage Pull (maximum) - Low Downdrives | 86.4 ton (US) |

| Cutting Drum Speed - RA560 | 33.5, 38.8 and 43.8 rpm |

| Cutting Drum Speed - RA750 | 32.8, 37.4 and 45.2 rpm |

| Haulage Pull (maximum) - High Downdrives | 90 ton (US) |

| Haulage Speed (maximum) - Low Downdrives | 102.9 ft/min |

| Machine @ 60 Hz | |

| Seam Range | 1.8-4.5 m (71-177 in) |

| Cutting Drum Diameter | 1600-2500 mm (63-98.5 in) |

| Haulage System | AC inverter drive |

| Operating Voltage | 4160 V |

| Available Cutting Power | 2 × 600 kW (2 × 805 hp); 2 × 740 kW (2 × 998 hp); 2 × 900 kW (2 × 1,207 hp) |

| Typical Machine Length - Drum Centers | 46.15 ft |

| Machine Weight - Approximate | 77 ton (US) |

| Pump Motor | 48 hp |

| Installed Power | Up to 2086 kW (Up to 2,797 hp) |

| Minimum Pan Width | 40.6 in |

| Haulage Power | 2 × 125 kW (2 × 168 hp) |

| Body Thickness | 24 in |

| Haulage Pull (maximum) - Low Downdrives | 96.8 ton (US) |

| Haulage Pull (maximum) - High Downdrives | 100.8 ton (US) |

| Cutting Drum Speed - RA750 | 39.4, 44.9 and 54.2 rpm |

| Haulage Speed (maximum) - Low Downdrives | 102.9 ft/min |

| Cutting Drum Speed - RA560 | 40.2, 46.6 and 52.6 rpm |

| Haulage Speed (maximum) - High Downdrives | 98.8 ft/min |

| Powerpack - PP2 | |

| Type (1) | Single powerpack with less parts to fail and less tasks for quick and easy maintenance |

| Type (5) | For use with ISO 68 hydraulic oils |

| Type (2) | Fixed displacement pump (Standard) – Capacity at 50 Hz: 49 L/min (10.8 gal/min); Capacity at 60 Hz: 59 L/min (13 gal/min); Operating Pressure: 280 bar (4,060 psi). Fixed displacement pump (Option) – Capacity at 50 Hz: 62 L/min (13.6 gal/min); Capacity at |

| Type (7) | Reliable low-voltage pump motor rating of 30 kW @ 50 Hz (48 hp @ 60 Hz) |

| Type (3) | Robust hydraulic reservoir of 140 L (37 gal) capacity |

| Type (4) | Integral monitoring transducers (oil level and temperature) |

| Type (6) | Available with 6 section valve bank |

| Type (8) | Optional boost valve for accelerated gate end operations (recommended for cowls) |

| Electrical Control Box - ECB2 | |

| Type (2) | High current carrying capacity of 400 amps; accommodation of trailing cables up to 120 mm² (4/0 AWG) |

| Type (5) | Containing cutter motor contactors, circuit breakers, control transformer, current monitoring, HV fuses, earth leakage and visible disconnect |

| Type (3) | Internal chassis can be ‘bench built,’ tested and stored |

| Type (1) | This flameproof module contains most of the shearer electrical control and power distribution components. |

| Type (4) | LV circuit breakers resettable through FLP cover (reduced downtime) Powerful PMC Evo-S control system with state-of-the-art Ethernet communication |

| Haulage Transformer Box - HTB2 | |

| Type | Flameproof module containing the main 253 kVA haulage transformer, power supplies, auxiliary transformer, drive system circuit breaker, hydraulic pump motor, and a 250 kW (335 hp) 600V AC inverter drive with integrated regenerative breaking. |

| Electrical Material | |

| Type (2) | All electrical material is designed and certified to IEC standards and also complies with other regional and national standards, such as MSHA, GOST, MA, ATEX and DGMS, as well as Australia’s New South Wales and Queensland regulations. |

| Type (1) | This model of shearer is available with headlights, cameras, methane monitoring, end displays and audible alarms. |

| Hydraulic Material | |

| Type (2) | The hoses are assembled to Hose Assembly Standard DIN 20066. |

| Type (1) | All hose assemblies are to ISO 6805 and proof tested according to EN ISO 1402. |

| Type (3) | Hose selection and routing per industry standard best practices (including MDG41, ISO TS 17165N2 and SAE J1273) |

| Type (4) | Cat® hoses are aligned with the standards of MSHA, DGMS and MA |

| Water Material | |

| Type (4) | Cat hoses are aligned with the standards of MSHA, DGMS and MA. MDG 41 compliant hoses are available for Australia. |

| Type (3) | Hose selection and routing per industry standard best practices (including MDG41, ISO TS 17165N2 and SAE J1273). |

| Type (2) | The hoses are assembled to Hose Assembly Standard DIN 20066. |

| Type (1) | All Cat hose assemblies are designed according to ISO 6805 and proof tested according to EN ISO 1402. |

| Type (6) | Onboard water filtration (optional) |

| Type (5) | Stainless steel fittings (optional) |

| Health Monitoring | |

| Type | A comprehensive health monitoring system is available, including oil levels and temperatures, flows, pressures and vibration analysis. |

| Machine Automation and Communication | |

| Type (3) | Fast Ethernet Broadband communication allows enhanced diagnostics and analysis |

| Type (8) | Pan Angle Measurement System (PAMS) enabling fully automated gate end cutting sequences without machine operator interactions (optional) |

| Type (2) | Modular design allows individual configuration (from basic monitoring and protection to advanced automation) to meet customer requirements |

| Type (7) | Shearer automation levels available: – Standard Machine Control – Basic Automation – Advanced Automation (including face alignment horizon control) |

| Type (9) | Horizon Control from PMC-R Controls to allow corrections to Floor and Roof drum cutting heights (optional) |

| Type (4) | Control system architecture with backup functionality |

| Type (10) | Shearer Remote Operation to allow machine control from a safe remote location outside the face (optional) |

| Type (1) | Distributed, high-performance PMC-S control system for machine control, health monitoring, system protection and predictive maintenance |

| Type (6) | Machine performance algorithm “advanced motor and speed control” for increased machine uptime, coal production and longer service life |

| Type (5) | Widespread use of intrinsically safe components for improved serviceability and maintenance |

| Ranging Arms - RA750 | |

| Type (7) | Available cutter motors – 620 kW and 750 kW at 50 Hz (998 hp and 1,207 hp at 60 Hz) |

| Type (6) | Maximum drum diameter of 2500 mm (98 in) |

| Type (8) | Robust cowl drive mechanism (optional) |

| Type (1) | Reconfigurable gear cassettes for adaptation of drum speeds |

| Type (4) | Transmission rating of 750 kW at 50 Hz (1,207 hp at 60 Hz) |

| Type (3) | Quillshaft transmission protection |

| Type (5) | Separate oil compartments for high speed and planetary section (optimal cooling and lubrication) |

| Type (9) | Vibration monitoring (optional) |

| Type (2) | Integral monitoring transducers |

| Mainframe - MF2 | |

| Type (4) | Modular design enabling for selective overhauls |

| Type (2) | Maximum protection of electrical boxes, providing the highest level of flameproof integrity, protects gearboxes against torsion |

| Type (3) | Split mainframe is available in case of transportation limitations |

| Type (1) | High structural integrity and absorption of all cutting and haulage forces, providing maximum protection for all major units |

| Type (5) | Spray boom retrofittable |

| Type (6) | Mainframe add additional weight to cope with the most challenging cutting conditions |

| Dimensions (Approximate) - Low | |

| AFC Pan Width - Minimum | 41 in |

| Diameter - Shearer Cutting Drum | 63 in |

| Machine Height - Over Main Body | 58 in |

| Clearance from Drum to AFC Toeplate | 12 in |

| Ranging Arm Cutting Drum Diameter | 63 in |

| Height - Top of Machine Main Body | 58 in |

| AFC Pan Width - Maximum | 53 in |

| Cutting Height - Minimum | 71 in |

| Ranging Arm Length - Hinge to Drum | 111 in |

| Distance Between Ranging Arm Hinge Points | 332 in |

| Maximum Cutting Drum Overall Width | 45 in |

| Cutting Height - Maximum | 155 in |

| Shearer Drum Undercut of Floor | 16 in |

| Distance Between Drums with Arms Horizontal | 554 in |

| Vertical Tunnel Clearance | 24 in |

| Distance Between Trapping Shoe Centers | 252 in |

| Dimensions (Approximate) - Mid-Low | |

| Clearance from Drum to AFC Toeplate | 12 in |

| Distance Between Trapping Shoe Centers | 236 in |

| Machine Height - Over Main Body | 60 in |

| Distance Between Drums with Arms Horizontal | 554 in |

| Ranging Arm Cutting Drum Diameter | 75 in |

| AFC Pan Width - Maximum | 53 in |

| Ranging Arm Length - Hinge to Drum | 111 in |

| Maximum Cutting Drum Overall Width | 45 in |

| Distance Between Ranging Arm Hinge Points | 332 in |

| Vertical Tunnel Clearance | 26 in |

| Shearer Drum Undercut of Floor | 20 in |

| Diameter - Shearer Cutting Drum | 75 in |

| AFC Pan Width - Minimum | 41 in |

| Cutting Height - Maximum | 163 in |

| Cutting Height - Minimum | 75 in |

| Height - Top of Machine Main Body | 60 in |

| Dimensions (Approximate) - Mid-High | |

| Vertical Tunnel Clearance | 28 in |

| Distance Between Trapping Shoe Centers | 258 in |

| Maximum Cutting Drum Overall Width | 45 in |

| Cutting Height - Maximum | 170 in |

| Shearer Drum Undercut of Floor | 24 in |

| Height - Top of Machine Main Body | 62 in |

| Ranging Arm Length - Hinge to Drum | 111 in |

| Diameter - Shearer Cutting Drum | 87 in |

| Distance Between Ranging Arm Hinge Points | 332 in |

| Clearance from Drum to AFC Toeplate | 12 in |

| Distance Between Drums with Arms Horizontal | 554 in |

| Ranging Arm Cutting Drum Diameter | 87 in |

| AFC Pan Width - Minimum | 41 in |

| AFC Pan Width - Maximum | 53 in |

| Cutting Height - Minimum | 87 in |

| Machine Height - Over Main Body | 62 in |

| Dimensions (Approximate) - High | |

| Clearance from Drum to AFC Toeplate | 12 in |

| Ranging Arm Length - Hinge to Drum | 111 in |

| Distance Between Trapping Shoe Centers | 236 in |

| Cutting Height - Minimum | 98 in |

| AFC Pan Width - Maximum | 53 in |

| Shearer Drum Undercut of Floor | 26 in |

| Diameter - Shearer Cutting Drum | 98 in |

| Maximum Cutting Drum Overall Width | 45 in |

| Height - Top of Machine Main Body | 65 in |

| Vertical Tunnel Clearance | 31 in |

| Distance Between Ranging Arm Hinge Points | 332 in |

| AFC Pan Width - Minimum | 41 in |

| Machine Height - Over Main Body | 65 in |

| Ranging Arm Cutting Drum Diameter | 98 in |

| Cutting Height - Maximum | 180 in |

| Distance Between Drums with Arms Horizontal | 554 in |

| Ranging Arm | |

| RA560 (9) | Vibration monitoring (optional) |

| RA560 (6) | Maximum drum diameter of 2000 mm (79 in) |

| RA560 (3) | Quillshaft transmission protection |

| RA560 (4) | High-speed gears and idlers rated for 560 kW at 50 Hz (900 hp at 60 Hz), hub rated for 750 kW at 50 Hz (1,200 hp at 60 Hz). |

| RA560 (8) | Robust cowl drive mechanism (optional) |

| RA560 (7) | Available cutter motor – 500 kW at 50 Hz (805 hp at 60 Hz) |

| RA560 (5) | Separate oil compartments for high speed and planetary section (optimal cooling and lubrication) |

| RA560 (2) | Integral monitoring transducers |

| RA560 (1) | Reconfigurable gear cassettes for adaptation of drum speeds |

| Haulage Unit - HU150 | |

| Type (8) | Quillshaft transmission protection |

| Type (9) | Machine parking brake (optional) |

| Type (2) | Transmission rating of 150 kW (200 hp) providing designed redundancy |

| Type (6) | Haulage unit accepts hydraulic motor for installation and face recovery |

| Type (1) | Haulage motor limited to 125 kW (168 hp) |

| Type (4) | Absolute encoder for accurate machine position detection (no reset devices at gate ends needed) |

| Type (3) | Transmission reduction of 137:1 |

| Type (5) | Closed loop control for accurate load-sharing and increased service life of rackbar and sprocket |

| Type (7) | Oil temperature monitoring |

| Type (10) | Vibration monitoring (optional) |

| Dust Suppression | |

| Available Solutions | Wide range of dust suppression solutions available: – Body sprays – Spray booms – Sloughing plate sprays – Spray rings (in place of cowls) – Shearer clearers |

| Remote Control | |

| Type (2) | Color graphic display |

| Type (3) | Tilt, drop and impact detection |

| Type (1) | Lightweight handheld device |

| Downdrive | |

| Type (4) | Transmission rating of 125 kW (168 hp) for low downdrives/150 kW (200 hp) for high downdrives |

| Type (1) | Configurable for direct and indirect drives |

| Type (5) | Trapping shoe with replaceable wear inserts (for indirect drives), safe and easy to replace |

| Type (7) | Reconfigurable downdrive and shoe posts for different pan widths and seam heights |

| Type (3) | Designed for superior serviceability with quick and easy access for maintenance (Higher variants use cartridge design for top drive wheel assembly/lower versions provide access via top cover) |

| Type (6) | Suitable for all rack type systems |

| Type (2) | Fully removable, modular gearbox |

Taking the Shearer to the Next Level

Your shearer is the most critical part of your longwall production process. That's why high-performance longwall operations demand shearers that deliver the highest productivity, availability and reliability. Cat shearers were always designed to meet these demands. But Caterpillar has taken them to the next level.

Survival of the Fittest

To do this, we invested heavily in refining our successful range of shearers. We started by reviewing and analyzing all more recent shearer installations and setting goals to improve productivity, availability and reliability. This was not a re‑design, but an evolution – keeping the best tried-and‑tested features of the existing design while using the latest findings from science and technology to improve features and add new ones.

Shear Performance

With high-powered ranging arms and haulage units, Cat shearers cut and load up to 5000 tonnes (5,500 tons) per hour and more, depending on mining conditions. The unique, one-piece mainframe design offers maximum structural integrity and service life. The mainframe is available as a split unit in the event of transportation limitations. Featuring the superior Jumbotrack shearer haulage system, the shearer also offers advanced integrated automation and communication options.

Key Improvements

Cat shearers incorporate numerous new features and benefits. These are presented in the following pages by category. The key improvements include:

- Extremely powerful PMC™ Evo-S control system with state-of-the-art Ethernet communication

- Improved innovative downdrive design

- Ranging arm with longer service life

- Further development of the modular haulage and electrical control box

- Enhanced power pack with easy access

- Online vibration monitoring with VibraGuard™

- Clear wiring and use of plug and play for easy maintenance

- Trapping Shoe Ix (Insert Exchange) for longer service life, safe and easy to replace

- Future-proof design allowing upgrades – such as stronger ranging arms and haulage units or addition of coal sizer – during rebuild

Machine Mainframe

The unique mainframe of the Cat shearer is one of its key features. The fabricated structure of the mainframe with cast ranging-arm hinge points results in an extremely robust design not only to meet the toughest mining conditions and ensure reliability and long service life, but also to handle even higher cutting and haulage forces in the future. A split mainframe is available in case of transportation limitations.

Benefits:

- High structural integrity and absorption of all cutting and haulage forces, providing maximum protection for all major units

- Maximum protection of electrical boxes, providing the highest level of flameproof integrity

- Improved access for maintenance and ease of overhaul and repair

- Versatility of application due to fully modular construction

- Flexible and cost-effective equipment management

- Independent unit exchange and selective overhaul

- Long service life

- Low operational costs

- High reliability

Innovative Trapping Shoe

Trapping shoes attach the shearer to the haulage rack system, part of the armored face conveyor, allowing the shearer to be hauled up and down the face. A new type of trapping shoe developed by Caterpillar – the Trapping Shoe Ix – offers numerous advantages over the conventional design:

- Greater safety and ease of handling during replacement

- Faster replacement

- Greater flexibility

- Longer service life

- Lower operating costs

The patent-pending Trapping Shoe Ix continues the Caterpillar principle of designing products with separate structural and wear parts to allow quick and easy replacement of surfaces subject to wear. The new design cuts the weight that has to be handled during replacement from more than 500 kg to less than 50 kg per insert, and cuts the time required for exchange to a fraction of the previous time. Because the weight handled is so much lower, changeout can take place anywhere along the face – previously this work had to be done at the gate ends, where heavy lifting equipment was available.

Extended Service Life

The inserts have the same wear area as conventional shoes and are articulated. This – combined with the fact that the shoe does not have to exert as much pressure, resulting in a lower point load – means less wear. Field tests of the Trapping Shoe Ix showed its service life to be 50 percent longer than conventional trapping shoes.

Ranging Arms

Our shearers cover a wide range of cutting heights and mining conditions. They have installed cutting power to provide world-class production in the toughest mining conditions: The EL2000 with a cutting power of up to 750 kW (1,200 hp).

- High levels of installed power available in each class

- Cutting depth of 0.85 m (2.79 ft) and 1.0 m (3.28 ft)

- A range of cutter motors available to suit all mining conditions

- Compact design for optimum coal-loading performance

- Fast and accurate positioning of the ranging arm through two-speed technology and a more powerful lifting cylinder

- Modularity allows fast in-situ maintenance and repair

- Improved lubrication results in lower operating temperatures

- New, more robust cowl drives

Strong Arm

The safety factor for the ranging arm has been further increased. Gear rating, bearing life and redundancy have also been increased, leading to longer overhaul intervals based on typical usage.

Coal Sizer

Cat shearers can be supplied with an optional rugged coal sizer, currently with up to 200 kW (320 hp) of installed power for maximum productivity in high seams or difficult mining conditions. The coal sizer can be ordered separately for installation during rebuild or overhaul.

Haulage System

Modular Haulage System

Caterpillar has further developed its modular haulage concept with increased power rating, gear rating, bearing life and redundancy, leading to longer overhaul intervals based on typical usage. The haulage system is a simple design capable of achieving cutting speeds of up to 32 m/min (105 ft/min), with improved reliability and longer service life. The fully modular haulage gearbox is located in the shearer mainframe and does not form part of the shearer structure. The haulage system offers:

- Simple construction, improved reliability and longer service life

- Fully proven load-sharing system

- Reduced cost

Power Pack

The power pack has been re-engineered to provide increased functionality, optimized performance and better access to filtration units via simplified layout. Both of the following units are modular, with drawer units providing easy access and upgrade.

Transformer Box

- Features closed-loop control with measurement of speed, not power

- Transforms to 600V for haulage units' frequency converter motors

- Connectorized cables for reduced wiring and quick, clear installation

- Temperature monitoring and water cooling

Control Box

- Plug and play

- Easy to maintain

- Quick and easy troubleshooting

Downdrive System

Downdrive

An innovative downdrive design results in longer bearing life, increased gear rating and greater modularity for simplified maintenance. Height adjustment of the shearer is relatively easy and is achieved with replacement of the downdrive to allow adaptation to changing seam conditions. Every mainframe is designed to take the full range of downdrive arrangements to fit a wide range of seam heights.

- Fully modular design

- Easy maintenance access

- Fully articulating shoe

- High pull and maximum life

Tested for Reliability

Downtime is extremely expensive for operators – costs continue to add up while nothing is produced. This is why Caterpillar ensures that our superbly engineered shearers are up to the job. That's why each shearer design – which is optimized for maximum availability – is subjected to rigorous in-house testing to ensure that there are no unpleasant surprises when units are in service. Shearer production quality assurance falls into three main categories: lubrication verification, endurance block load testing and production load testing.

Lubrication Verification

Ranging arms and haulage units are subjected to an intense test regime to establish the optimum oil-level requirements to suit all mining conditions. The units are mounted on purpose-designed test rigs that are positioned to simulate the gradient of the underground seam. A suite of tests is performed with a range of different gradients and arm positions to represent even the most severe mining conditions. The units are operated until stable temperatures are achieved at all gradients. This establishes the minimum, maximum and optimum oil quantities for all conditions.

Endurance Block Load Testing

This test applies loads far in excess of those encountered during normal mining operations, ensuring that the shearer can operate reliably at the installed power ratings. Ranging arms or haulage units are mounted on purpose-designed test rigs in a back-to-back configuration driven by a suitable test motor. The endurance block load test imposes loads from 100% to 175% to ensure that the ranging arm design meets the requirements of the most demanding applications. Input torque, losses and output torque are monitored during the test, as are bearing, gear and shaft temperatures. Vibration is monitored by dedicated sensors. Oil samples are collected at intervals for analysis, as the presence of metal in the oil can indicate excessive component wear. On completion of the endurance test, units are dismantled for a full internal and external inspection to verify that the design is fit for purpose.

Production Load Testing

After successful endurance block load testing, the same test rigs are used to carry out production load testing of all ranging arms and haulage units. The test gradually increases the load up to full load. All temperatures and vibration points are monitored during the test, and oil samples are again collected for analysis.

Proven Productivity

This extensive range of tests ensures the highest possible availability of shearers in service and maximum return on investment for your longwall installation. Nothing is left to chance in ensuring that our shearers are unsurpassed in reliability.

Shearer Automation

Industry-leading Automation from the Pioneer of State-based Automation

Caterpillar has developed a state-of-the-art distributed automation system for the control, monitoring and protection of the shearer. Its modular design allows it to be configured to meet individual control needs, from basic monitoring and protection to advanced automation and data transmission. The PMC™ Evo-S control system with state-of-the-art Ethernet communication and backup functionality allows the shearer to be operated even if the overall control system is not functioning. In 2002, State-Based Automation was invented and launched. Using this technology, Caterpillar now offers a comprehensive range of automation products.

Power and Flexibility

With extensive computer power installed and simple upgrade to new features, Cat shearer automation is fit for the future. Components connect into the network rather than directly to a central computer, simplifying installation, wiring, maintenance and troubleshooting. The shearer is equipped with a state-of-the-art industry PC in a flame-proof housing with plenty of computing power, allowing flexibility to upgrade to future features such as condition monitoring.

A Programmable Logic Controller (PLC) takes care of basic machine control tasks, ensuring that coal is mined. Unlike competitor systems, the modularity of the longwall system and control allow the longwall to operate in “fault-tolerant” mode, even when there is a problem with the overall automation system. In other words, integrated automation does not prevent control via individual PLCs in order to keep production up and running.

The Net is the Control

The shearer control system uses a state-of-the-art Ethernet bus, resulting in a drastic reduction in wiring and a huge increase in flexibility. There are no interfacing problems, as equipment connected to the network only needs to be able to communicate via Internet Protocol. Commissioning, maintenance, upgrades and troubleshooting are much easier and faster, and equipment is self-configuring. The few cables that are used are standard Ethernet cables rather than application-specific cables – cutting costs and simplifying spare parts inventories.

Flameproof housings are no longer required, simplifying installation and speeding up maintenance. New modules are based on standardized CIOS™ modules (configurable input output system), resulting in a plug and play approach to upgrades. No reprogramming is necessary.

Remote control and diagnosis are also possible for all components. And because of the Ethernet-based approach, the failure of one component does not impact the whole system.

Intrinsic Safety

More components designed to be intrinsically safe means simpler installation and speedier maintenance. New modules are based on standardized CIOS™ modules, resulting in a plug and play approach to upgrades. Changes to the system only require commissioning changes – such as mounting and connection of sensors. No replacement of control software is required. Remote control and diagnosis are also possible for all components. And because of the Ethernet-based approach, the failure of one component does not impact the whole system. This not only supports the unique “fault- tolerant” mode, which allows the longwall to continue to operate when there is a problem with the overall automation system, but also, through systematic isolation, allows faulty units to be identified while production continues.

PMC™ Evo-S Offers Reliability from Day One

- Robust cables and plugs

- Minimized cabling due to network approach

- Vibration-tested components

- Designed for the working environment

Condition Monitoring

Visualization

Visualization not only provides a graphical representation of current operating conditions, but can also display historical conditions and a graphic display of trends. An automated longwall is a highly complex system with many interacting components generating time-variant data. Visualization gives operators a better understanding of the overall system, allowing them to further optimize operations. VLongwall provides a system overview and access to the dedicated visualization modules VShield, VDrive, VPlow and VShearer. It also gives access to VTrend for trend analysis and VGraph3D for waterfall plots of the entire longwall.

VibraGuard™

VibraGuard™ allows trained personnel to predict machine component wear, avoid unplanned downtime and set alarms to warn the operator if monitored machine components run the risk of damage. This comprehensive protection backs long life and high availability of your valuable mining equipment.

- Permanent online monitoring and protection of equipment instead of sporadic offline measurements

- Assists in the prediction of machine component wear

- Alarms warn the operator if monitored components are at risk of damage

- When utilized by trained personnel, VibraGuard™ makes repairs predictable and helps avoid unplanned downtime

- Repair work can be done largely without stress

- Allows timely procurement of spare parts

- Transfers data to a surface control center PC for detailed analysis and evaluation

Modular Control

PMC™ Evo-S brings state-of-the art processor performance underground. Designed by the market leader in shearer automation, the advanced Cat automation package allows improved utilization of manpower in a safe environment; with increased yield from any given seam section, faster haulage speeds, improved face management and increased life of all longwall equipment, including AFC and shields.

Automation systems match your needs – from basic to highly sophisticated – while remaining easy to install, operate and maintain. The modular control concept is:

- Easily expandable based on modular design

- Ready for integration of highly sophisticated technologies and devices

- Equipped for XML-based interfaces to third- or fourth-party systems

Making it Easy

- Cat self-configuring controls and standard interfaces such as Ethernet allow quick and easy system configuration changes with no programming effort

- Ready for future technologies such as high-quality condition monitoring, including vibration monitoring

- Easy and flexible adaptation to existing data environments

- Greater use of Ethernet, standard connectorization and PMC™ control family mean greater simplicity, reduced spares inventories and shorter downtimes

- Standardization and modularization allow quick and easy customization of components and systems

Fast Troubleshooting

- Widespread use of intrinsically safe components allows large-scale fault diagnosis under power

- Remote access to most components down to I/O level

- Diagnosis from surface or by Cat Mine Control Center

- Managed switches and field bus coupler (FBC) allows selective routing: – Permits sequential disable and enable of components and/or communication routes – Isolation of faulty units until next repair shift allowing production to continue

Less Maintenance Effort

- Widespread use of intrinsically safe components in PMC™ Evo-S reduces time-consuming opening of flame-proof housings in the event of faults.

- Quick and easy exchange of modules.

Modularity is Strength

Modularity is a key feature of the Cat shearer. It results in independent major units, each driven by its own dedicated electric motor and housed within or attached to a robust mainframe unique to the Cat range. Control systems are also modular.

This modular design offers maximum availability – through “fault-tolerant” mode operation – and the flexibility to meet even the most demanding customer requirements by upgrading components such as the ranging arm.

The Cat Shearer Product Line

The EL2000 incorporates all the features and benefits that have been established with the Cat shearer range in a compact, rugged machine designed to meet the demands of high productivity in low- to medium-seam applications from 1.80 to 4.50 m (70 to 177 in). High installed power is a feature of the EL2000 shearer, with up to 750 kW (1,200 hp) in a compact design. The haulage system is tailored to the needs of high-productivity medium-seam applications with up to 125 kW (200 hp) AC drives.

Benefits:

- High level of structural integrity provided by the unique Cat shearer mainframe design

- Maximized coal cutting and coal clearance ability

- Advanced automation for optimized performance and improved face management

Standard Equipment:

-

- Gate End Data Connection

-

- Powerline

- WLAN

Optional Equipment:

-

- Coal Sizer

-

- 100 kW (134 hp)