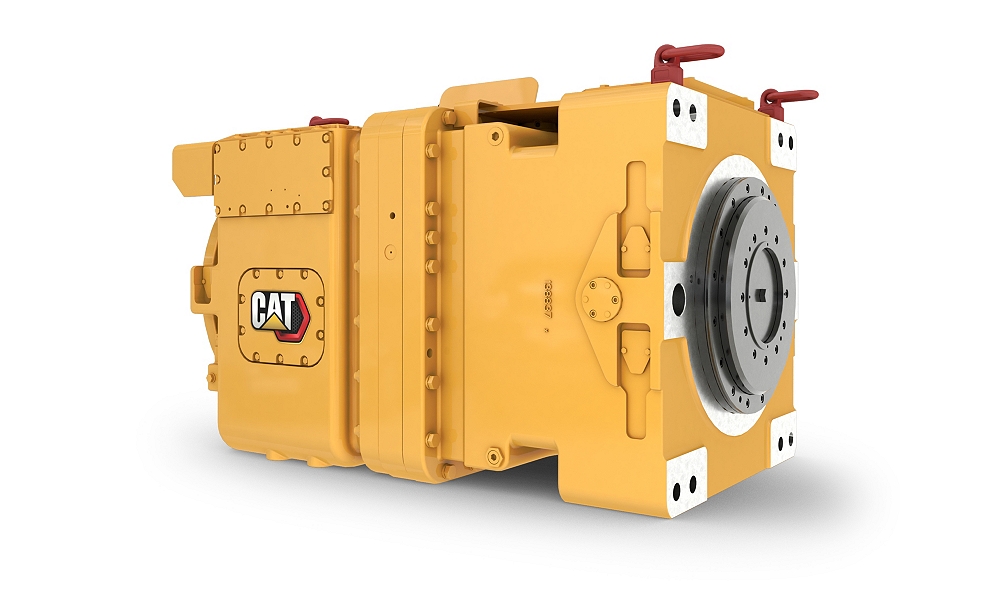

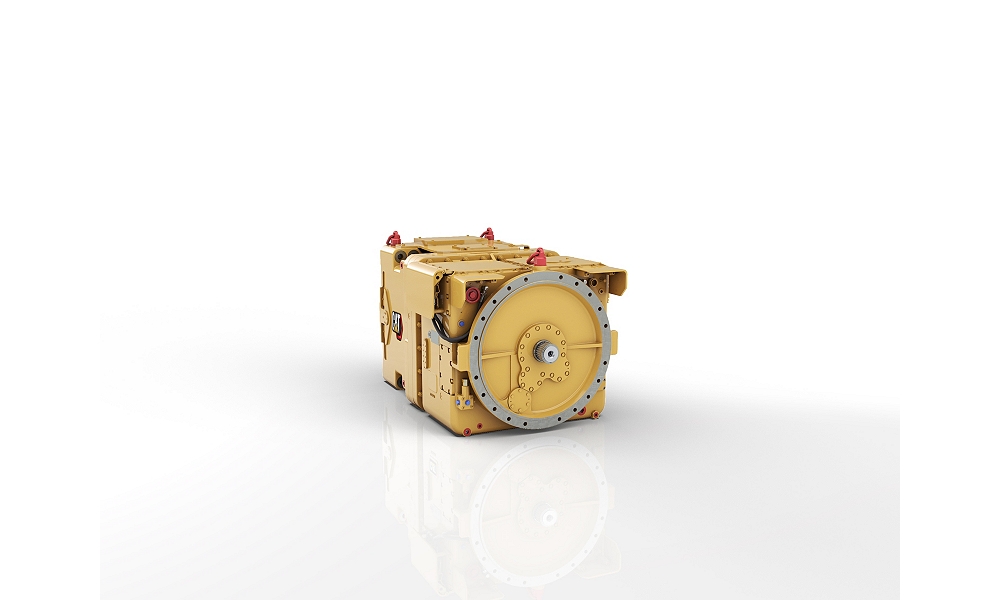

Cat® Controlled Start Transmission (CST) drive systems optimize the use of power for maximum production capacities. Ever more powerful systems require ever more horsepower, heavier chains and faster conveyor speed with maximum availability. What was needed was a truly intelligent drive system for face conveyors, which led our engineers to develop the Controlled Start Transmission (CST) drive system meeting the following requirements: • Currently available power up to 1200 kW (1,950 hp) per transmission unit • Safe startup of the face conveyor • Full utilization of the installed power • Highly durable components • Compact dimensions • High level of efficiency

| Specifications | |

| Maximum Input Speed - Motor Speed | 1,500 rpm @ 50 Hz (1,800 rpm @ 60 Hz) |

| Weight - Without Oil - In-line Drive System | 16094 lb |

| Maximum Output Torque for a Short Duration (3 sec.) | 479415 ft-lb |

| Shaft Design | |

| Output Shaft with Internal Toothing | DIN 5480-N 320×10 |

| Input Shaft - Cylindrical | DIN 5480-W 120×4 |

| Capacity | |

| KP-65 CST - Oil Quantity | 211 gal (US) |

| P-65 CST - Gearbox Weight - Without Oil | 16094 lb |

| KP-65 CST - Gearbox Weight - Without Oil | 23980 lb |

| P-65 CST - Oil Quantity | 132 gal (US) |

| Requirements of Cooling Water | |

| Required Cooling Water Quantity | 6.6 gal/min |

| Maximum Water Inlet Temperature | 25° C/298.15 K (77° F/298.15 K) |

| Dimensions | |

| P-65 CST - Length | 74.3 in |

| KP-65 CST - Width | 60.2 in |

| KP-65 CST - Height | 41.7 in |

| P-65 CST - Height | 41.7 in |

| KP-65 CST - Length | 114.6 in |

| P-65 CST - Width | 44.1 in |

| Maximum Output Torque (for 3 sec) Tmax [N·m] | |

| Rated Power P @ 50 Hz (n = 1,480 rpm) - Ratio i [-]: 33 | 1200 kW |

| Rated Power P @ 50 Hz (n = 1,480 rpm) - Ratio i [-]: 50 | 800 kW |

| Rated Power P @ 50 Hz (n = 1,480 rpm) - Ratio i [-]: 39 | 1000 kW |

| Rated Power P @ 60 Hz (n = 1,800 rpm) - Ratio i [-]: 33 | 1,958 hp |

| KP-65 CST/P-65 CST | 479415 lb/ft |

| Rated Power P @ 50 Hz (n = 1,480 rpm) - Ratio i [-]: 28 | 1200 kW |

| Rated Power P @ 60 Hz (n = 1,800 rpm) - Ratio i [-]: 28 | 1,958 hp |

| Rated Power P @ 60 Hz (n = 1,800 rpm) - Ratio i [-]: 50 | 1,305 hp |

| Rated Power P @ 60 Hz (n = 1,800 rpm) - Ratio i [-]: 39 | 1,632 hp |

| Rated Power P @ 60 Hz (n = 1,800 rpm) - Ratio i [-]: 45 | 1,468 hp |

| Rated Power P @ 50 Hz (n = 1,480 rpm) - Ratio i [-]: 45 | 900 kW |

| Typical Application | |

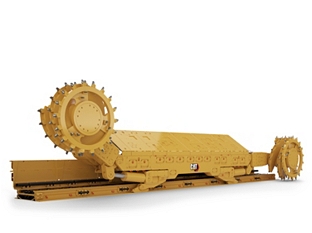

| Description | Chain Type Longwall Machinery like Armored Face Conveyors (AFC) |

Startup

Benefits

- Staggered no-load motor startup: Minimum voltage drop in the electrical supply system

- Soft start of the face conveyor: Minimum stress on all drivetrain components at startup

- Synchronized startup and use of motor kinetic energy: Maximum total torque is available to facilitate startup of fully loaded conveyors

Load-sharing

Benefits

• Accurate load-sharing between the drives: Full utilization of available power, avoiding motor overheating and resultant downtime even with a chain showing different pitch along the face

Overload Protection

Benefits

• Instant, effective overload protection: Excessive chain forces and the risk of instant chain failures are virtually eliminated. Chains, sprockets and transmission units incur less wear because shock loads are absorbed.

Motor Braking Feature

In order to restart the drives safely, the operator has to wait a considerable time (up to 3 minutes) until the motors come to a standstill. Motor braking leaves an adjustable residual pressure on the CST clutch, minimizing the time for the motor to stop and the resultant downtime.

PMC™-D and PMC™-V

The PMC™-D is typically dedicated to each gearbox or drive individually. It contains all necessary hardware to control all functions of a drive system effectively. The unit can be connected to an internal mounted distribution box as typically used in CST gearboxes for the connection of sensors and actuators. The PMC™-V contains 24 keys for easy operation and a 4” VGA display. Graphical trends, warnings and any error messages can be displayed. The interface is available in various languages such as English, Chinese, German and Russian. The PMC™-V displays all available gearbox data including transducer values, status information, global and local parameters, network status, etc. Parameters can be easily changed using the 24-key numerical keyboard. Important system parameters are password protected.

V-Drive Visualization Software

The software also stores all CST data and undertakes analysis and trending of sensor values. It allows export of data to office applications such as electronic spreadsheets. Chinese, German and Russian versions of the software are also available.

Field Experience

Benefits

- Minimal slip during operation: Minimal energy and heat losses, maximum overall efficiency

- CST clutch mounted on low-speed output shaft: Ideal load discharge at the chain sprocket, very precise clutch control

- Integrated emergency operation feature: Fallback mode allows operation with semi-automatic mode and emergency mode

- Integrated CST drive system is considerably shorter than other drive systems: Less space required in narrow entries, very few external components

- High flexibility in operation: All parameters for startup, load-sharing and overload protection freely selectable

ICDS - Integrated CST Drive System

The ICDS has a special asynchronous motor from Baldor Electric Company, with rated power of currently up to 1200 kW (1,950 hp). The nominal motor running torque is 7640 N·m (5,635 lb-ft) at full nominal speed. The maximum AFC starting torque (breakdown torque) is 3 × 19 100 N·m (14,090 lb-ft). Space is provided for integrated protected mounting of PMC™-D controls and other accessories. The power cable can be equipped with a Victor plug. The ICDS allows direct measurement of motor power at the PMC™-D controls.