The 785 Large Mining Truck was Caterpillar’s first entry into the mining industry more than three decades ago and has been a proven performer on sites around the world ever since. And now it’s the first to combine a game-changing level of efficiency with industry-leading physical availability to deliver the next generation of productive hauling. It all starts with the operator, who sits in a state-of-the-art environment designed for efficiency and equipped with features that increase comfort, automate functions, provide real-time information and boost confidence. The 785 also delivers significant improvements in serviceability and reliability, enhanced connectivity and easier technology integration. These improvements — and more — take an already proven truck to the next level of productivity.

| Weights - Approximate | |

| Nominal Rated Payload (36.00R51 Tires) | 162 ton (US) |

| Rated Gross Machine Weight (36.00R51 tires) | 564000 lb |

| Nominal Rated Payload (33.00R51 Tires) | 158 ton (US) |

| Rated Gross Machine Weight (33.00R51 tires) | 550000 lb |

| Chassis Weight (33.00R51 Tires) | 187736 lb |

| Chassis Weight (36.00R51 Tires) | 192959 lb |

| Body Weight | 57779 lb |

| Note (1) | Consult your tire manufacturer for maximum tire load |

| Note (2) | Chassis weight with full fuel and fluids, standard & mandatory attachments, hoist, body mounting group, rims, and tires. |

| Note (3) | Unlined HP Body. Body weight varies depending on body selection and configuration. |

| Engine | |

| Gross Power - SAE J1995 | 1600 hp |

| Engine Model | Cat 3512E |

| Net Power - SAE J1349 | 1509 hp |

| Emissions Rating | Fuel Optimized |

| Bore | 6.7 in |

| Stroke | 8.5 in |

| Displacement | 3573 in³ |

| Note (1) | Net Power advertised is the power available at the flywheel when the engine is equipped with air intake system, exhaust system, and alternator. |

| Note (2) | U.S. EPA Tier 4 Final / EU Stage V available for applicable markets. |

| Note (3) | Additional fuel optimized selectable power ratings: 1,450 hp |

| Capacity - HP Body - 100% Fill Factor | |

| Heaped (SAE 2:1)* | 110 m3 / 144 yd3 |

| Struck | 84 m3 / 110 yd3 |

| Cab | |

| Air Conditioning | HFC - 134A refrigerant: 24,500 Btu/h |

| Heater / Defroster | 33300 Btu/h |

| ROPS Standards (1) | ROPS (Rollover Protective Structure) meets ISO 3471:2008 for Operator and ISO 13459:2012 for Trainer. |

| FOPS Standards | FOPS (Falling Objects Protective Structure) meets ISO 3449:2005 Level II for Operator and ISO 13459:2012 Level II for Trainer. |

| Suspension | |

| Type | Self-contained nitrogen/oil cylinders, pin-to-pin mounting, top & bottom double shear clevis attachments |

| Effective Cylinder Stroke - Front | 12.6 in |

| Effective Cylinder Stroke - Rear | 6.5 in |

| Rear axle - Oscillation | +/- 5.4 degrees |

| Body Hoists | |

| Type | Twin, two-stage hydraulic cylinders with snubbing valve. |

| Pump Flow - High Idle | 223 gpm |

| Relief Valve Setting - Raise | 2500 psi |

| Body Raise Time - High Idle | 15 s |

| Body Lower Time - Float | 15.6 s |

| Body Power Down- High Idle | 15.5 s |

| Braking System | |

| Service Brakes | Four-Corner, Wet Disc, Oil Cooled, Hydraulically Actuated |

| Front Wet Disc Brake Surface Area | 9487 in² |

| Rear - Wet Disc Brake Surface Area | 13908 in² |

| Standards | Service and Secondary: ISO 3450:2011 |

| Parking Brake | Four corner, multi disc, spring applied, hydraulically released |

| Steering | |

| Steer Angle | 25.1 ° |

| Turning Diameter - ISO 7457:1997 (33.00R51 tires) | 96.6 ft |

| Steering Standards | ISO 5010:2019 |

| Service Refill Capacities | |

| Fuel Tank | 410 gal (US) |

| Diesel Exhaust Fluid Tank | 36 gal (US) |

| Cooling System | 126 gal (US) |

| Crankcase | 54 gal (US) |

| Front Wheels - Each | 7.1 gal (US) |

| Differential - Final Drives | 139 gal (US) |

| Steering Tank | 29 gal (US) |

| Steering System - Includes Tank | 31 gal (US) |

| Brake/Hoist Tank | 135 gal (US) |

| Brake Hoist System - Includes Tank | 143 gal (US) |

| Torque Converter - Transmission System - Including Sump | 46 gal (US) |

| Final Drives | |

| Type | Double reduction, planetary with full floating axles. |

| Differential Ratio | 2:10:01 |

| Planetary Ratio | 10.83:1 |

| Total Reduction Ratio | 22.75:1 |

| Tires | |

| Optional Tires | 33.00R51 |

| Optional Tire | 36.00R51 |

| Rims | 610 mm (24") Rims (optional). 660 mm (26") Rims (optional). |

| Note (1) | Quick Change Rims optional. |

| Note (2) | Caterpillar recommends the customer evaluate all job conditions and consult tire manufacturer for proper tire selection and TKPH (TMPH) capabilities. |

| Weight Distributions - Approximate | |

| Front Axle - Empty | 48% |

| Rear Axle - Empty | 52% |

| Front Axle - Loaded | 33% |

| Rear Axle - Loaded | 67% |

| Note | Weight distributions optimized with Cat body. |

| Dimensions (All dimensions are approximate. MSD II Body, 33R51 tires, unloaded machine.) | |

| Height - Top of ROPS | 17.09 ft |

| Overall Body Length | 39.32 ft |

| Inside Body Length | 27.29 ft |

| Overall Length | 39.23 ft |

| Wheel Base | 17 ft |

| Rear Axle - Tail | 12.56 ft |

| Ground Clearance | 3.29 ft |

| Dump Clearance | 3.7 ft |

| Loading Height - Empty | 17.39 ft |

| Inside Body Depth - Maximum | 9.15 ft |

| Overall Height - Body Raised | 39.48 ft |

| Operating Width | 24.72 ft |

| Centerline Front Tire Width | 15.91 ft |

| Engine Guard Clearance | 3.41 ft |

| Overall Canopy Width | 24.81 ft |

| Outside Body Width | 22 ft |

| Inside Body Width | 19.72 ft |

| Front Canopy Height | 19.8 ft |

| Rear Axle - Clearance | 3.25 ft |

| Centerline of Rear Dual Tire Width | 14.06 ft |

| Overall Tire Width | 20.59 ft |

| Sound | |

| Sound Standards | The operator sound pressure level, 77 dB(A) with direct drive and 75 dB9A) with optional clutch, tested to ISO 6396:2008. |

| Transmission | |

| Forward - 1 | 7.4 mile/h |

| Forward - 2 | 10 mile/h |

| Forward - 3 | 13.7 mile/h |

| Forward - 4 | 18.5 mile/h |

| Forward - 5 | 25 mile/h |

| Forward - 6 | 35.6 mile/h |

| Reverse | 7.2 mile/h |

| Top Speed - Loaded | 35.6 mile/h |

| Note | Maximum travel speeds with standard 33.00-R51 tires. |

PRODUCTIVITY

- The Advanced Power Electronic Control Strategy (APECS) enables faster cycle times thanks to more continuous torque and rimpull.

- Forward momentum and torque are maintained through each shift, with optimum gear selection resulting in faster acceleration.

- The 785 delivers a 6% higher TKPH /TMPH (tonne-kilometer-per-hour / ton-mile-per-hour) thanks to larger tire options that allow allow mines to take advantage of higher speeds, particularly in flat, long-haul, high-speed applications.

- Productivity-enhancing features such as Hill Start Assist with Anti-Rollback, Enhanced Traction Control, Dynamic Stability Control (DSC), Anti-lock Brake System (ABS), Machine Speed Limiting and Cruise Control improve machine responsiveness and controllability while improving cycle times and reducing operator fatigue.

SAFETY

- Wide, slip-resistant surfaces and hand rails, plus an optional powered access ladder, improve access and egress.

- Superior control is delivered by a patented braking system that provides immediate, fade-resistant braking and retarding.

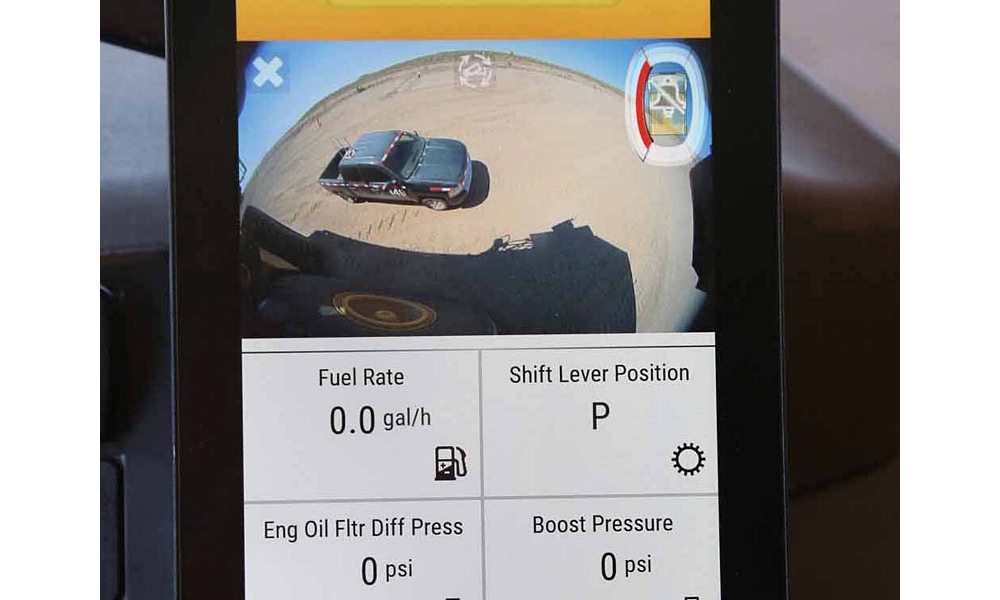

- Visibility is enhanced by an optional 360-degree Surround View camera, which offers a bird�s-eye view.

- The Cat MineStar� Object Detection system combines radar and camera systems to warn operators about light vehicles or stationary hazards within the immediate vicinity of their machines.

- The optional Driver Safety System alerts the operator if fatigue or distraction are detected.

OPERATOR COMFORT

- The cab provides 34% more operator space than D-Series models. It�s 17% wider and offers 11% more legroom and 19% more shoulder room. Controls, levers and switches are positioned for ease of use.

- With 40% less Sound Pressure Level (SPL), automated temperature control and cab filtration, operators enjoy a safer and more comfortable environment.

- A walkthrough cab with fully adjustable center console, easy-to-adjust seat and increased leg room makes the cab ideal for operators of all sizes.

- The next generation seat is four-point-restraint ready and incorporates features like thigh tilt and extensions, air adjustable side and lumbar bolsters, and heated and cooled cushions.

- Operators enjoy a more comfortable ride thanks to smoother transitional shifting and reduced shift jerk levels provided by APECS controls.

OPERATOR EFFICIENCY & PRODUCTIVITY

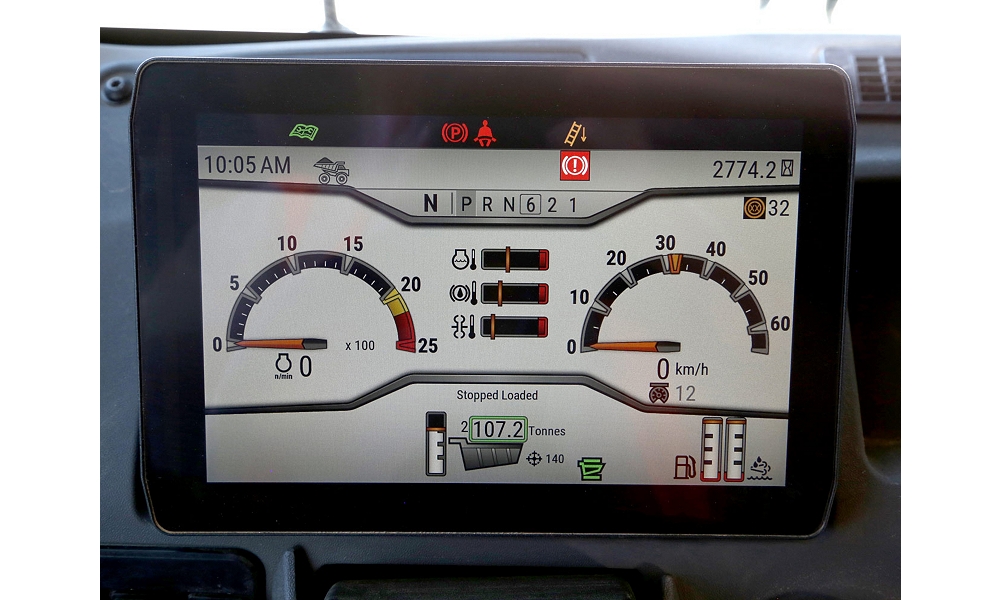

- Higher resolution displays improve access to information. Machine data, controls and guidance information are consolidated onto two ideally located 10-inch screens.

- The optional Auto Hoist feature automatically raises the body and controls engine speed, simplifying operation and minimizing cycle times.

- Speed coaching gives operators real-time feedback on how to operate the truck to maximize its productivity.

- The payload monitoring system comes with more accurate measurements, providing immediate feedback to the operator.

SERVICEABILITY

- The new modular HVAC (heating, ventilation and air conditioning) system improves reliability and consolidates components so the entire system can be removed and replaced quickly.

- A modular radiator reduces engine removal and installation time and enables rebuilds to be completed off the truck.

- New remote flash and remote troubleshooting capabilities provide immediate access to the latest software updates and make it possible to troubleshoot the machine remotely.

- Time spent on regular maintenance procedures is reduced thanks to features such as extended-interval filters with ground-level access; grouped service points and optional centralized service center; cleaner hydraulic and electrical routings; SOS and pressure ports for faster, safer oil sampling and troubleshooting; and fluid-level sight glasses.

- A 100% airless electric start option eliminates air system maintenance from the machine and improves uptime.

DURABILITY AND LONG LIFE

- Longer-life components, extended service intervals and easier maintenance deliver consistently high mechanical availability.

- A reduction in torque spikes and fewer variations in engine speed, made possible by APECS controls, deliver longer engine and powertrain component life.

- The 785 frame uses a box-section design, incorporating two forgings and 21 castings in high-stress areas with deep penetrating and continuous wrap-around welds to resist damage from twisting loads without adding extra weight. The mild steel frame provides flexibility, durability and resistance to impact loads.

- Component life is enhanced thanks to the standard rear-axle continuous filtration feature. Cleaner oil helps promote lubrication that leads to longer life

- The frame, powertrain, engine and components are built to be rebuilt � delivering multiple lives of like-new performance at a fraction-of-new price.

CAT BODIES

- Caterpillar designed and manufactured bodies are integrated with the chassis as a unit to optimize performance and incorporate optional Tier 4 components, including body exhaust heat.

- The lightweight Mine Specific Design (MSD) body is designed with built-in carryback reduction features (front wall curved transition and corner pop-out plates) and is available with optional application-specific body liners.

- Intended for tough applications, the heavy-duty Dual Slope body provides excellent load retention, maintains a low center of gravity with optimum load distribution and reduces shock loading.

SUSTAINABILITY

- The 785 is designed to use less fuel, which reduces engine emissions, and there is zero fuel burn during retarding. The Tier 4 Final engine reduces NOx and particulate matter.

- The Cat 3512E engine�s 12-cylinder four-stroke design uses long, effective power strokes for more complete fuel combustion and optimum fuel efficiency.

- The 785 engine is compatible with diesel fuel blended with lower-carbon intensity fuels such as biofuels and renewable fuels.

- Features like oil renewal systems, continuous rear axle filtration, extended life filters and longer maintenance intervals decrease the amount of waste contributed to the environment.

- By rebuilding machines and components, the Cat Rebuild and Cat Reman programs preserve raw materials, conserve energy and reduce emissions.

VERSATILITY

- The 785 is available in a cold-weather configuration that makes it ideal for mines operating in frigid environments. It features automatic engine thermal management, a variable fan speed for low temperature operation, and an electric- or air-start option.

- The 3512E engine gives you the ability to select the power rating to match your current fleet performance or to achieve faster cycle times.

- The 23% net torque rise provides unequaled lugging force during acceleration, on steep grades and in rough underfoot conditions.

- Tire options allow you to select the tire that best matches your application, with a larger tire for flat, long, high-speed applications. The frame is designed to maintain the same turning diameter while accommodating larger tires.

- The 785 is available in two options to meet emissions standards. The optional Tier 4 Final engine meets the strictest standards while the LRC engine is available in those countries that are less regulated.

TECHNOLOGY SOLUTIONS

- MineStar Fleet is a fleet monitoring system that can be used to measure, manage and maximize the overall hauling operation.

- Additional MineStar Detect offerings include Awareness, which can provide warnings, and the in-cab Driver Safety System, which intervenes when it detects fatigue or distraction.

- Machine health and condition monitoring solutions enable a proactive approach to maintenance.

BETTER ACCESS TO DATA

- Next generation connectivity delivers faster data transfers, better access to data, consistent data communication, more actionable data, improved data analytics and new diagnostic capabilities.

- The backbone of the next generation machine is 100 Mbps two-wire ethernet communication across the machine controllers, sensors that are optimized for data analytics, and robust controls.

- Advanced connectivity on the 785 truck is enabled by standard cellular 4G/LTE, optional dual mode 4G/LTE and Satellite Product Link�, or locally installed Wi-Fi.

- Every machine from the factory comes with Product Link Elite as a standard offering. This solution enables the truck to collect and transmit information into locally-hosted or cloud-hosted applications.

Standard Equipment:

-

- Electrical

-

- 24V electrical system, low maintenance batteries (2) 93 amp-hour

- Alarm, backup

- Brushless alternator, 225 amp

- Ground accessible power control box: Ethernet VIMS� port and VIMS lamp; Engine starter; transmission and battery lockouts

- Jump start/battery charge receptacle

- LED payload indicator lamps

- LED Lighting system: Back-up and hazard lights, Curb lights, (one) RH side, (one) LH side, Turn signals (front and rear), Engine compartment lights, Headlights with low-high beam selector, Ladder light and service deck lights, Stop/tail lights

-

- Fluids

-

- Extended Life Coolant to � 35� C (� 30� F)

-

- Operator Environment

-

- 5V USB charging port

- 12V auxiliary power connection

- Cup holders

- Diagnostic connection port COM3 and Ethernet

- Delayed Engine Shutdown

- Dome courtesy light and map lights

- Entertainment radio ready: Speakers, Optional Antenna (AM/FM/WB/satellite radio), Radio mounting provisions and 12V power supply

- Fire suppression ready

- Floor mat, multi-piece & replaceable

- Gauges and indicators panel: Critical oil and coolant temperatures; Fuel and DEF level (if applicable); Engine system, brake and transmission fault indicators; Operator selectable max. machine speed by rotary dial; Speedometer, Tachometer

- Heated mirrors, right and left

- Hoist, body control

- Interactive touchscreen vehicle information display: Day/night mode; Action alarm; Quad gauge display

- Operator and trainer air suspension seats

- Operator Door Power Window

- Provision for customer accessory mounting

- Push button secure start

- Retractable front visor

- ROPS cab, insulated/sound suppressed

- Stairway and walkway access, 600 mm (24 in)

- Steering wheel, tiltable, telescopic

- Self-filling to windshield washer fluid from AC condensate

- Storage locations for operator gear

- Three point seat belt for operator seat

- Windshield wiper, intermittent control / washer

- Unitized hydraulic powered HVAC with automatic temperature control

- Ventilated operator seat

-

- Power Train

-

- 33R51 power train with standard rims

- Cat 3512E engine: Automatic engine and DEF thermal management (if applicable); Automatic low voltage idle management; Air cleaner with precleaner (two); Turbocharging (four) with air-to-air aftercooler; Mechanical Electronic Unit Injector (MEUI�-A) fuel system; Automatic starter protection; Automatic ether starting aid

- Hydraulic braking system: Automatic Resistive Braking control (ARC), adjustable and automatic; Brake release motor (towing); Engine over speed protection; Extended life brake disc material; Hill start assist/Anti roll back strategy; Oil-cooled, multi-disc (front and rear) � Service, Resistive braking, parking, secondary; Park brake integrated with gear selector

- Transmission :Six-speed, automatic power shift with Electronic Clutch Pressure Control (ECPC); Advanced Productivity Electronic Control Strategy (APECS); Body-up reverse neutralizer; Body-up shift inhibitor; Downshift/reverse shift inhibitor; Directional shift management; Enhanced Traction Control System; Programmable top gear; Oil level sensor; Neutral coast inhibitor; Neutral start switch; Lock-up torque converter; Rear axle continuous lubrication/filtration

-

- Other Equipment

-

- Auxiliary "buddy" dumping quick connect

- Auxiliary connection 'user defined shutdown'

- Auxiliary steering quick connect (towing)

- eOMM

- Fast fill fuel and DEF remote fill system

- Guards for rotating components

- Hill Start Assist

- Hydraulic Filters, 1,000 hours

- Remote flash software and troubleshooting

- Secondary steering (automatic)

- Tie off points

- Tow hooks (front) and tow pin (rear)

- Sight glasses for hydraulic oils

- S�O�S? ports

- Vital Information Management System (VIMS)

-

- Cat Technology Products

-

- Cyber security

- Integrated object detection system with touchscreen display

- Tire Payload Monitoring System 2 (TPMS 2)

- Product Link� Elite

Optional Equipment:

-

- Electrical

-

- Auxiliary rear work lights, (one) LH side

- Digital Payload Display

- LED Lighting system: Additional lighting package, Auxiliary VIMS, Body rear, Seat & park brake

- Workshop horn

-

- Truck Bodies

-

- MSD II body: 100 m3 (131 yd3)

- Dual slope body: 78 m3 (102 yd3)

- Body specific side wall and tail extensions

- Customizable body liner packages

- Body heat exhaust

- Rock ejectors

- Rear body lighting group: Directional signals, Stop/tail lights

-

- Fluids

-

- Extended Life Coolant to � 50� C (� 58� F)

-

- Operator Environment

-

- Emergency stop

- Deluxe Cab: Advanced cabin filtration system; Catwalk and handrails for rear cab access; Heated, cooled and ventilated front seat; Power right side window; Suspended companion seat; Storage tray

-

- Power Train

-

- No air � electric starter with 93-amp hour batteries (four), electric horn and automatic lubrication system

- Hydraulic braking system: Advanced ground control with Anti-lock Braking System (ABS) and Dynamic Stability Control (DSC)

- Variable speed fan drive

- Transmission: Engine pre-lubrication system; Rear axle continuous lubrication/filtration with cooler

- Turbine air starter with air tank, air horn and automatic lubrication system

-

- Other Equipment

-

- 2560 L (676 gal) fuel tank (non-Tier 4)

- Body heat exhaust

- Bumper towing � center pin kit

- Cold weather start (block heater)

- Communication Ar � Minestar� radio

- Fire extinguisher, portable

- Five piece crankcase guards

- Fuel heater, fuel water separator

- Fuel tank mud guard

- Gauge, brake wear indicator

- Ground accessible fluid service center, hydraulic and coolant

- Hub odometer, kilometers

- Powered access stairway

- Rim Diffuser

- Wheel chocks

- Wireless Electronic Technician (ET)

- Working at heights protection

-

- Cat Technology Products

-

- Cruise control

- 360 degree surround view camera

- 4G cellular/satellite dual mode

- Connectivity bundle (includes: wireless operator ID, bluetooth key FOB to start)

- Driver Safety System (DSS) 4.0 Ready

- Minestar GPS

- Minestar communication group (enables: Minestar Fleet, Aux, and Truck Spotting)

- Oil Renewal System (ORS) (non-Tier 4)

- Road Analysis Control (RAC)

- Minestar Command Autonomous-ready