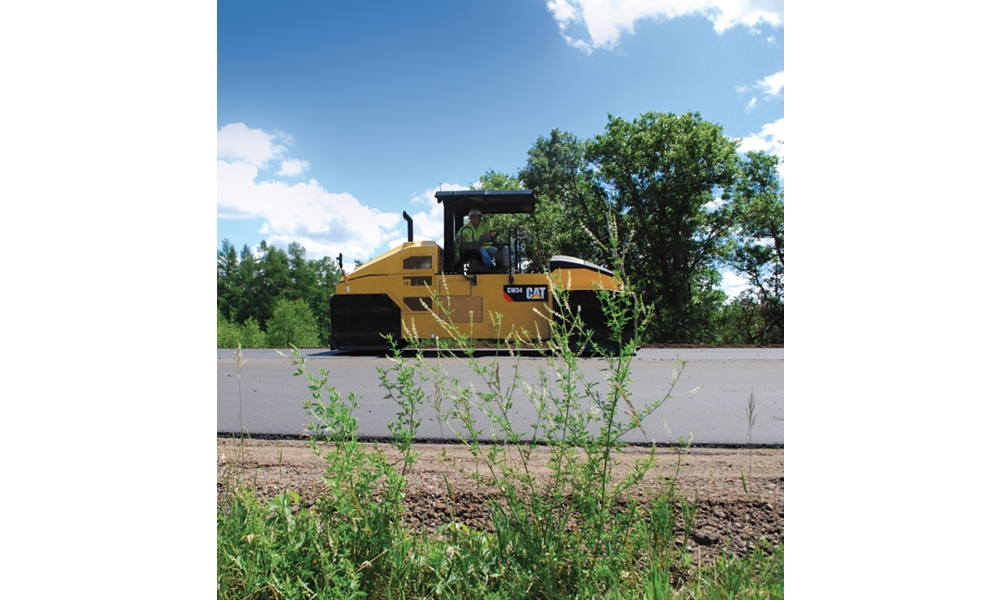

The CW34 is an eight wheel pneumatic roller that features a modular ballast system and flexible operating weight of 10 000 kg to 27 000 kg (22,050 lb – 59,525 lb). This machine offers excellent visibility, ECO-mode operation, even compaction, and excels on a variety of materials due to its flexible air-on-the-run capability.

| Weights | |

| Operating Weight - Standard Machine Empty | 22050 lb |

| Operating Weight - Maximum Ballast | 59525 lb |

| Average Weight per Wheel | 3571 lb |

| Average Weight per Wheel - Maximum Ballast | 7451 lb |

| Average Weight per Wheel - No Ballast | 2755 lb |

| Operating Weight - Maximum Water Ballast | 28660 lb |

| Operating Weight - Maximum Wet Sand Ballast | 35275 lb |

| Operating Weight - No Ballast | 22050 lb |

| Operating Specifications | |

| Compaction Width | 82 in |

| Turning Radius - Inside (2) | 20 ft |

| Rolling Width | 82 in |

| Ground Clearance | 10 in |

| Number of Wheels | 8 |

| Travel Speed - Maximum | 12 mile/h |

| Turning Radius - Inside (1) | 240 in |

| Turning Radius - Outside | 342 in |

| Engine | |

| Bore | 4.13 in |

| Stroke | 5 in |

| Engine Model | C4.4 |

| Gross Power | 133 hp |

| Dimensions | |

| Height - ROPS | 118 in |

| Height - Steering Wheel | 96 in |

| Maximum Machine Height | 118 in |

| Overall Length | 210 in |

| Overall Width | 85 in |

| Tires | |

| Tires | 13/80 R20 |

| Service Refill Capacities | |

| Fuel Tank Capacity | 71 gal (US) |

| Water Spray Tank Capacity | 100 gal (US) |

Versatile Compaction Performance

Compaction Width

Eight 13/80 R20 rubber tires provide overall compaction width of 2090 mm (82") with 25 mm (1") overlap.

Flexible Ballast

Ballast options include modular and non-modular steel, sand, and water. The 6.5 metric ton (7.1 U.S. ton) modular steel can be easily added or removed through bolt-on side panels. The internal, non-modular steel consists of 6.1 metric tons (6.7 U.S. ton). Also, a 3 cubic meter (793 gal) water-tight chamber with baffled compartments prevent surge, and balance weight.

Oscillating Tires

Oscillating front and rear tires deliver vertical and horizontal forces that reduce air voids, providing surface uniformity. Heat retention covers trap heat to keep the tires warm and prevent pick-up. They can be easily stored when not in use.

Air-on-the-Run

The 13/80 R20 rubber tires can be equipped with the optional air-on-the-run system that enables the operator to quickly adjust tire pressures to increase or decrease static loads for optimal surface quality.

Exceptional Visibility and Control

Operating Environment

The sliding and pivoting operator station rotates 90° to either side for ultimate comfort and control. The new console design includes an LCD display and push button machine controls that simplify operation for an all-around comfortable operating environment.

Cat® Compaction Control

Dual Infrared Temperature Sensors

Dual infra-red sensors mounted on the front and rear of the machine deliver real-time readings that keep the operator informed of when to begin rolling and when to stop. This system helps operators avoid tender-zones that often occur in the 104º-110º C (219º-230º F) temperature range.

Pass-Count Mapping

Pass-count mapping helps operators achieve target density and increase roller efficiency. The system records and monitors pass patterns in order to display coverage. The system also helps operators optimize drum overlap, simplify nighttime operation, eliminate second guessing and prevent incomplete passes such as stopping short.

Temperature Mapping

Temperature mapping provides a visual readout of mat temperature in order to keep the machine in the proper temperature range. The system records and monitors temperature for future analysis of the proper temperature range.

Smooth Operating Powertrain

C4.4 Engine

The C4.4 engine meets U.S. EPA Tier 4 Interim and EU Stage IIIB emission standards and provides 98 kW (133.2 metric hp).

ECO-mode

Standard ECO-mode provides fuel efficiency and reduces sound levels.