.

Description

Technical Specifications

Benefits and Features

Equipment

360 View

The Cat® SE60 FM screed provides application versatility, easy set-up, and a wide paving range, making it the perfect match for urban streets, parking lots, rural roads and many other mid-sized applications. Front-mounted extenders easily navigate curbs, light poles, turnouts, and other obstacles.

| Weights | |

| Standard Weight | 7800 lb |

| Operating Specifications | |

| Standard Paving Range | 3.05 - 594 m (10' - 19' 6") |

| Maximum Paving Width | 25.5 ft |

| Maximum Paving Depth | 10 in |

| Heating Time - Maximum Width | 25 minutes |

| Heating Time - Standard Width | 15 minutes |

| Crown Range | -2.5% to 5% |

| Vibratory Speed Range | 0 to 3000 vpm |

| Extender Height Range | -41 mm to +6.5 mm |

| Extender Slope Range | 0% to 9% |

| Dimensions | |

| Minimum Width - Endgates Attached | 132 in |

| Transport Length - Tractor and Screed | 21.75 ft |

| Screed Plates Width, Front to Back, Main Screed | 24 in |

| Screed Plates Width, Front to Back, Extenders | 9 in |

| Length - Front to Back, Endgates Attached | 86 in |

| Length - Front to Back, Endgates Removed | 59 in |

Application Versatility

- The standard paving range of 3.05 m - 5.94 m (10' - 19' 6") and maximum width of 7.77 m (25' 6") provides a balance between urban and highway paving applications.

- Common applications include parking lots, urban and rural roads, subdivision streets, and highways

- Front-mounted extenders make maneuvering around abstacles easy

- by providing the ability to retract without first clearing material from the extender

- Power berm options provide the ability to create a 305 mm (12"), 457 mm (18"), or 609 mm (24")wide berms with a variable height up to 102 mm (4")

Quick Adjustment

- Trailing edge screed plate adjusters help maintain an even plane across the width of the screed in order to improve paving quaility and extend screed plate life

- Extender angle of attack is easily accessible from the top of the extender frame

- Inner and outer strike-off adjustments are connected to provide single point modification that ensures equal adjustment across the width of the screed

- Slope stops help maintain performance

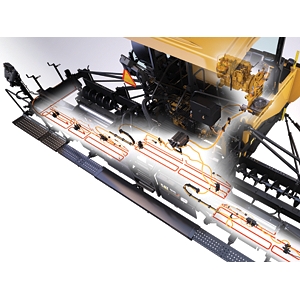

Smooth Material Flow

- Screed plate widths of 610 mm (24") on the main and 210 mm (9") on the extenders provide smooth flow

- Heated end gate option improves material flow for enhanced longitudinal joints

- The in-line extension cylinders and rigid frame design reduces deflection in the extenders for better mat quality

Quick Heat, Even Distribution

- Screed plate heating in as little as 25 minutes to 130º C (266º F)

- Exclusive zone monitoring allows heating to continue in the event of a temperature sensor failure

- U-shaped heating elements combined with zone monitoring helps ensure even heat distribution and smooth asphalt textures

Simple Operation

- Operating displays can be tailored to specific language requirements with multiple options available

- Exclusive 2-speed, proportional extender control provides smooth adjustment when transitioning paving widths

- Screed operating consoles are equipped with ratio adjustment for the augers and conveyors, providing the ability to modify material flow

- Power controls for extender slope and height enables operators to quickly manage mat angles and surface textures

Pendent Control (Option)

- Independent feeder system control includes manual and pause functions for each auger and conveyor

- Emergency engine stop feature

- Simple tow-point and berm attachment adjustments can be easily made with good visibility from the remote position

Cat® Grade Control (Option)

- Factory-integrated guidance system that helps remove irregularities from the surface and control mat thickness for increased production, lower operating costs, and higher profitability

- User-friendly system with text-based displays, split screen-mode, and on-the-go sensor selection

- Precise control driven by 10-point auto-calibration, true averaging with 5 transducers in each sensor, and cross-coupling feature that maintains elevation with height adjustment

Service and Repair Kits

- Paver and screed service and repair kits include the parts necessary to complete specific repairs

- Cat genuine parts are manufactured to precise specifications and designed for optimal performance and maximum uptime

- Repair kits are identified by a single part number to make ordering easy

- Select kits are available to be packaged as a kit by the dealer for over the counter purchases or through the dealer service shop

Standard Equipment:

-

- Operating Environment

-

- Level holder

- Lockable storage

- Shovel holder

-

- Power Controls

-

- Crown

- Slope

- Extender height

-

- Service And Repair

-

- Service repair kits

-

- Safety

-

- Horn

-

- Material Delivery

-

- Thickness screws _ clockwise or counterclockwise

- End gate_manual

Optional Equipment:

-

- Operating Environment

-

- Pendent control

- Visor _ LCD display

-

- Technology

-

- Cat Grade Control

-

- Safety

-

- Lights_roading

-

- Material Delivery

-

- Berm attachments

- Cutoff shoe

- Drop arm stabilizer

- End gate_heated

- End gate shoe_safety edge

- ExtensionsExtension _ 100 mm (4") high angle of attack

- Extension _ 305 mm (12")

- Extension _ 457 mm (18")

- Extension _ 610 mm (24")

- Screed plate _ dove tail

- Tapered notch extension with 457 mm (18")

- Vibratory sled _ utilized with tapered notch