How an Industrial Generator Works

Category: Rental

A generator serves as a standby source of electrical power that is ready to operate during an interruption to the main power supply. Without a reliable generator, a company could experience a significant loss of revenue during an outage and possibly put the safety of its workers and customers at risk. Most industrial generators are designed to deliver emergency power — they will start automatically when the electricity from the utility provider shuts off and then return to standby mode when power is restored.

A generator does not manufacture electricity. Instead, it works via a scientific principle known as electromagnetic induction to convert mechanical or chemical energy into electrical energy. This occurs via the harnessing of the power of motion to force electrons from an external source through an electrical circuit, which transforms them into electrical energy.

Learn More

Components of an Industrial Generator

To help you gain a better understanding of how an industrial generator works, we’ll take a closer look at the essential generator components and examine the role each plays in its operation:

- Engine: The engine serves as the generator’s energy source — the larger the engine, the more power it is capable of supplying. Depending on the design, generators can operate on a variety of fuel sources such as diesel, natural gas, gasoline or propane.

- Alternator: The alternator, often referred to as the genhead, is where the conversion from mechanical to electrical energy occurs. The alternator consists of stationary and moving parts that combine to produce the movement of the electrons.

- Fuel system: The fuel system includes a tank that typically stores a six- to eight-hour supply of fuel, as well as a fuel pump, a pipe that runs from the tank to the engine and a return pipe.

- Voltage regulator: This device controls the voltage of the electricity produced during generation and facilitates the conversion from AC to DC when necessary.

- Cooling and exhaust systems: The cooling system prevents the generator from overheating during operation, while the exhaust system removes and disposes of the toxic fumes.

- Lubricating system: This system contains and delivers the engine oil that ensures a smooth operation and prevents premature wear of the generator engine’s numerous moving parts.

- Battery charger: Although an industrial generator operates via a fuel source, it requires battery power to start it up. The charger ensures the battery receives the necessary float voltage to maintain a sufficient charge.

- Control panel: The control serves as the generator’s nerve center by managing every aspect of its operation. Depending on the generator model, the control panel may include features such as engine and generator gauges, phase selector switches and engine control switches.

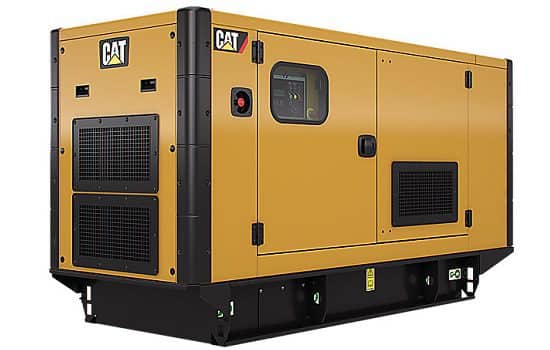

- Main assembly/frame: The frame provides the structure for the generator and houses and protects its vital components.

NMC offers a wide selection of top-quality new and used generators for every industrial application. You can also rent a reliable generator at a competitive daily, weekly or monthly rate from NMC The Cat Rental Store. Contact us to learn more today.

Contact Us