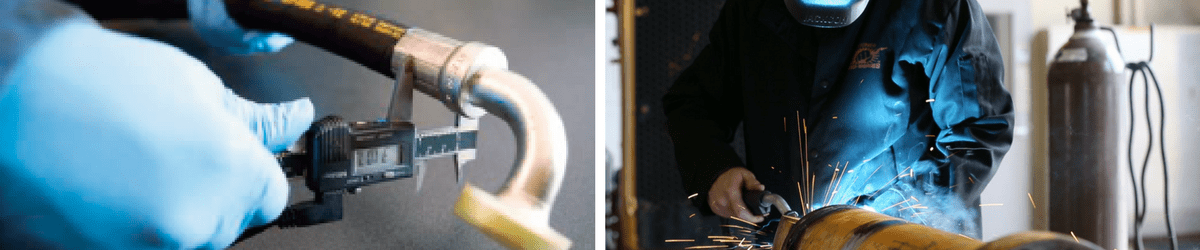

Hydraulic and Machine Shop

NMC Cat offers in-house hydraulic repair capabilities performed by expert technicians. Plus, many of our shops offer extended service hours to meet the needs of your business schedule.

OUR SPECIALIZED HYDRAULIC SHOPS OFFER:

- Hose fabrication

- Cat and non-Cat cylinder repairs, design, and fabrication

- Full production hone up to 32 inches

- Oversized cylinders – any length or diameter

- Re-rod

- Re-tube

- Re-seal

- Metal spray shafts

- Line boring

Hydraulic repair services available from NMC include cylinder repair, pump rebuild and custom hose assembly. Our specialized hydraulic cylinder equipment speeds disassembly and assembly, saving you time and money. NMC provides light honing of worn cylinders to clean up scratches and imperfections that can cut the performance of your hydraulic system and accelerate seal wear.

Prevent Hydraulic Problems Before They Occur

All machines use hydraulics in one form or another, and many rely almost entirely on hydraulics as the heart of their work output and operation. The decisions you make about your equipment’s hydraulic systems have a direct impact on your bottom line. Reliable, efficient, well-maintained hydraulics help you do more work each day, while keeping costs in line.

Custom Hydraulic Service

Custom Hydraulic Service (CHS), available through NMC, is a detailed inspection service designed for today’s hydraulic-intensive machines. Regular inspections – performed once a year or every 2,000 hours – help maintain peak performance.

CHS inspections include performance test, fluids analysis, a visual inspection and service solutions. Performance tests include engine performance, hydraulic cylinder drift and hydraulic system cycle times and pressure. During fluid analysis, oil samples are taken from the hydraulic compartment and are analyzed to determine contamination level, physical properties and wear material count. Visual inspection checks include the hydraulic system, engine and cooling system, cab, electrical system, undercarriage and ground engaging tools. Once the CHS inspections are complete, the results are analyzed by NMC technicians and if needed, changes are recommended to the maintenance schedule.

No matter how well built or well managed, your hydraulic system will eventually wear out. When your system needs service, NMC offers the repair options, trained technicians, proper tools and unmatched parts availability to get your machine running quickly and reliably.