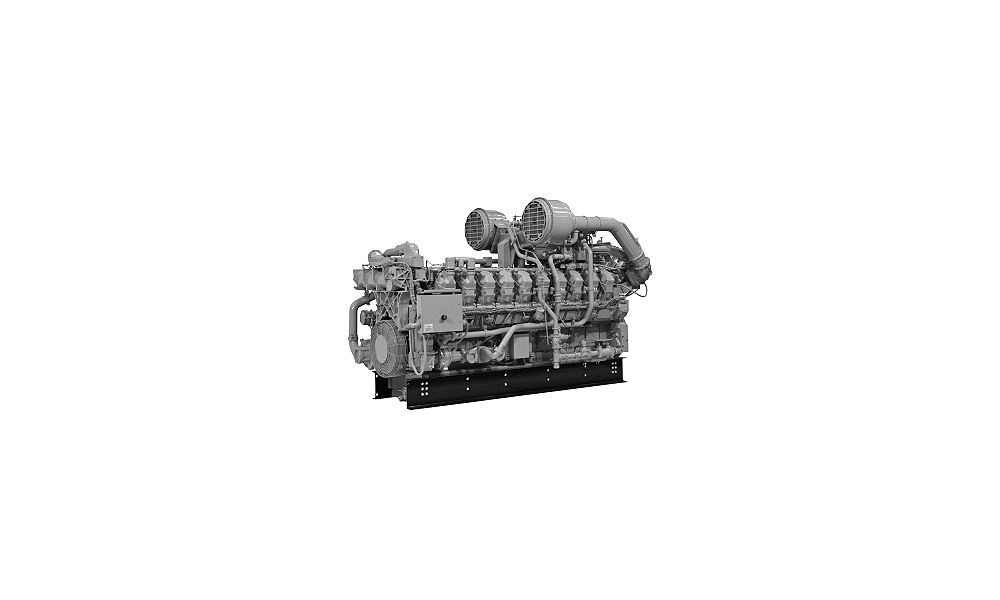

Cat® G3520 and G3520B Industrial Gas Engine. Ratings: 1104 bkW (1480 bhp) @ 1200 rpm and 1286 bkW (1725 bhp) @ 1400 rpm are NSPS site compliant capable with customer-supplied aftertreatment. For specific emission information, please consult your local Cat Dealer.

| General | |

| Bore | 170 mm (6.7 in) |

| Stroke | 190 mm (7.5 in) |

| Displacement | 86.3 L (5263 in³) |

| Engine Configuration | Engien - Continuous |

| Power Rating | |

| Minimum Power | 1480 hp |

| Maximum Power | 1725 hp |

| Frequency | 1200-1400 rpm |

| Engine Dimensions - Approximate | |

| Height | 2385 mm (94 in) |

| Weight - Net Dry | 11168 kg (24622 lb) |

| Length | 4180 mm (164 in) |

| Width | 1755 mm (69 in) |

Engine Design

- Built on G3500 LE proven reliability and durability

- Ability to burn a wide spectrum of gaseous fuels

- Robust diesel strength design prolongs life and lowers owning and operating costs

- Broad operating speed range at lower site air densities (high altitude/hot ambient temperatures)

- Higher power density improves fleet management

- Quality engine diagnostics

- Detonation-sensitive timing control for individual cylinders

Ultra Lean Burn Technology (ULB)

ULB technology uses an advanced control system, a better turbo match, improved air and fuel mixing, and a more sophisticated combustion recipe to provide: - Lowest engine-out emissions - Highest fuel efficiency - Improved altitude and speed turndown - Stable load acceptance and load rejection

Advanced Digital Engine Management

ADEM A3 engine management system integrates speed control, air/fuel ratio control, and ignition/detonation controls into a complete engine management system. ADEM A3 has improved: user interface, display system, shutdown controls, and system diagnostics.

Full Range of Attachments

Large variety of factory-installed engine attachments reduces packaging time.

Quality

Every Cat engine is manufactured to stringent quality standards in order to assure customer satisfaction.

World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including SOSSM sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

World-class Product Support Offered Through Global Cat Dealer Network

- Scheduled maintenance, including SOSSM sample

- Customer Support Agreements (CSA)

- Caterpillar Extended Service Coverage (ESC)

- Superior dealer service network

- Extended dealer service network through the Cat Industrial Service Distributor (ISD) program

Standard Equipment:

-

- Air Inlet System

-

- Axial Flow Air cleaner

- Cleanable

- Intermediate-duty with service indicator

-

- Control System

-

- ADEM A3 with integrated electronic throttle control

- Control panel

-

- Cooling System

-

- Two-stage charge air cooling

- Thermostats and housing

- Engine-driven jacket and aftercooler water pump

- Stainless steel aftercooler cores

-

- Exhaust System

-

- Dry exhaust manifolds

- Dry exhaust elbow

-

- Flywheels And Flywheel Housings

-

- SAE No. 00 flywheel

- SAE No. 00 flywheel housing

- SAE standard rotation

-

- Fuel System

-

- 7-50 psi gas supply

- Fuel system is sized for 800 to 1200 btu/scf (31.5 to 47.2 MJ/Nm3)

- Electronic fuel metering valve

- Gas pressure regulator

- Gas shutoff valve (GSOV)

-

- Ignition System

-

- ADEM A3

-

- Lubrication System

-

- Crankcase breather — top mounted

- Oil cooler

- Oil filter — RH

- Oil pan — 143 gal

- Drain valve

- Oil sampling valve

- Turbo oil accumulator

-

- Mounting System

-

- Engine mounting rails - 330.2 mm (13 in) industrial-type

-

- Power Take-offs

-

- Front housing — two-sided

- Front lower LH, RH, and upper RH accessory drives

-

- General

-

- Paint — Cat yellow

- Crankshaft vibration damper and guard

- CSA Certification, Class 1 Division 2, Group D - electrical system and instrumentation - includes ADEM A3 and control panel

Optional Equipment:

-

- Air Inlet System

-

- Round air inlet adaptors

-

- Charging System

-

- Charging alternator - CSA approved 24V, 65 A

-

- Cooling System

-

- Flexible connections

-

- Exhaust System

-

- Flexible fittings

- Flange and expander

-

- Fuel System

-

- Gas filter

-

- Instrumentation

-

- Communications module

-

- Lubrication System

-

- Lubricating oil

- Oil bypass filter

- Air prelube pump

-

- Power Take-offs

-

- Front stub shaft

- Pulleys

- Double damper

-

- Protection System

-

- Explosion relief valves

- Secondary GSOV

-

- Starting System

-

- Air starting motor with controls (90 psi or 150 psi)

- API B16.3 compliant piping

- Jacket water heater

- Barring group

-

- General

-

- Special paint

- Torsional vibration analysis

-

- Eu Certification

-

- EEC DOI certification

-

- Support

-

- Factory commissioning