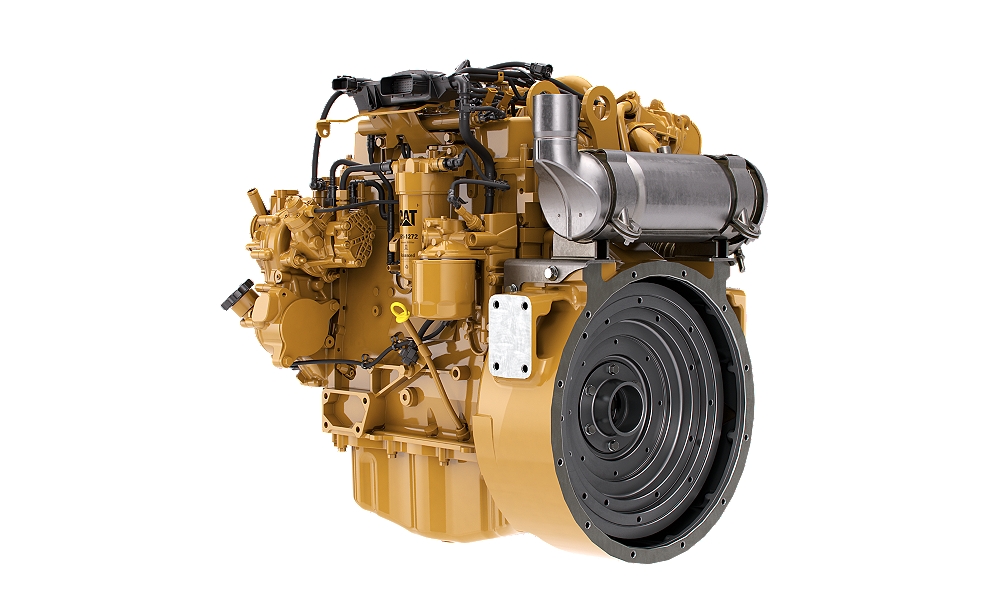

Cat® C3.4B Industrial Diesel Engines offer the perfect balance of durability, fuel efficiency and low emissions. The C3.4B Industrial Engine is offered in ratings ranging from 45-55.4 bkW (60-74.3 bhp) @ 2200-2500 rpm, which meet U.S. EPA Tier 4 Final, EU Stage IIIB emission standards. Industries and applications powered by C3.4B engines include: Agriculture, Aerial Lifts, Aircraft Ground Support, Bore/Drill Rigs, Chippers/Grinders, Compactors/Rollers, Compressors, Construction, Forestry, General Industrial, Irrigation Equipment, Material Handling, Mining, Mobile Earthmoving Equipment, Mobile Light Towers, Mobile Sweepers, Paving Equipment, Pumps, Specialty Ag Equipment, Trenchers, Turf and Landscaping and Underground Mining Equipment.

| Power Rating | |

| Maximum Power | 74.3 hp |

| Rated Speed | 2200 & 2500 rpm |

| Minimum Power | 60.3 hp |

| Emission Standards | |

| Emissions | U.S. EPA Tier 4 Final, |

| General | |

| Engine Configuration | In-Line 4, 4-Stroke-Cycle Diesel |

| Bore | 3.9 in |

| Stroke | 4.3 in |

| Displacement | 207.5 in³ |

| Compression Ratio | 17:01 |

| Aspiration | Turbocharged (T) |

| Combustion System | Direct Injection |

| Rotation from Flywheel End | Counterclockwise |

| Engine Dimensions - Approximate | |

| Length | 24 in |

| Width | 25.7 in |

| Height | 32.6 in |

| Weight - Net Dry - Basic Operating Engine Without Optional Attachments | 553.4 lb |

| Aftertreatment Dimensions | |

| Length | 21.3 in |

| Weight | 44 lb |

| Aftertreatment Dimensions* | |

| Diameter | 7.1 in |

Reliable, Quiet and Durable Power

World-class manufacturing capability and processes coupled with proven core engine designs assure reliability, quiet operation, and many hours of productive life.

High Performance

Leading-edge technology provides significant improvements in power, torque, fuel consumption and response. Technology includes single smart wastegated turbo systems, durable high pressure common rail technology, and closed circuit breathing system.

Fuel Efficiency

Fuel consumption optimized to match operating cycles of a wide range of equipment and applications while maintaining low operating costs.

Fuel & Oil

Tier 4 Interim or Tier 4 Final, Stage IIIB or Stage IV engines require Ultra Low Sulfur Diesel (ULSD) fuel containing a maximum of 15 ppm sulfur, and new oil formulations to support the new technology. Cat® engines are designed to accommodate B20 biofuel. Your Cat dealer can provide more information regarding fuel and oil.

Broad Application Range

Industry leading range of factory configurable ratings and options for agricultural, material handling, construction, mining, aircraft ground support, and other industrial applications.

Standard Equipment:

-

- Air Inlet System

-

- Induction manifolds

- Exhaust manifolds

-

- Control System

-

- Starter motor

- Alternator

- Electronic Control Unit

- Sensors for: engine speed, oil pressure, and coolant temperature

-

- Cooling System

-

- Cooling packs

-

- Flywheels And Flywheel Housing

-

- Flywheel housings

- Flywheel and starter rings

-

- Fuel System

-

- Fuel filter positions

- Common rail fuel pump and injectors

-

- Lube System

-

- Lubricating oil filters

-

- General

-

- Cold start capability to -20° C (-4° F)

- Paint: Caterpillar yellow, with optional colors available at request

-

- U.s. Epa Tier 4 Final, Eu Stage Iiib Aftertreatment/clean Emissions Control Equipment

-

- Diesel Particulate Filter (DPF)

- Diesel Oxidation Catalyst (DOC)

- Flex pipe connection kit with straight and 90° options for flexibility