.

Description

Technical Specifications

Benefits and Features

Equipment

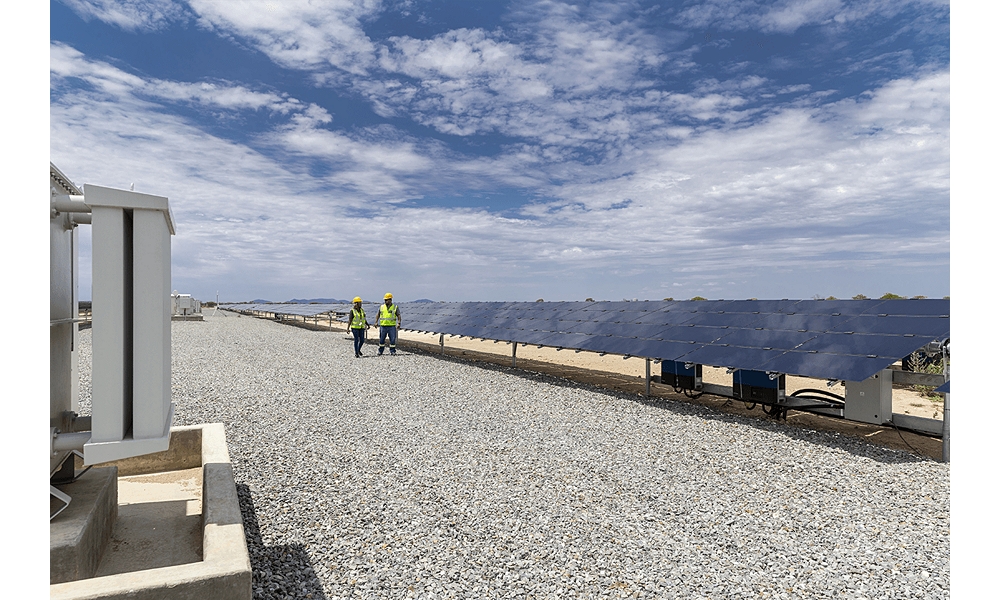

The mono crystalline PERC (passivated emitter rear cell) photovoltaic modules provide excellent performance with low temperature coefficient. The modules provide high efficiency and power per module, maximizing energy capture.

| Technical Summary | |

| Application | Compatible with 1000V and 1500V plant architectures |

| Module Type | Shingled mono crystalline PERC |

| Nominal Power | 405W to 420W per panel |

Higher Efficiency

- The panel design minimizes white space between solar cells, eliminates reflective metal lines on the cells, and lowers electrical resistance between cells, increasing efficiency compared to conventional commercial modules.

Increase Energy Production

- Linear shading response can generate more energy than conventional mono-crystalline modules.

More durable / Reliable

- Durability tested for mechanical load; Dynamic + Thermal Cycle + Humidity Freeze

- Harsh evironments; salt mist, amonia, dust and sand.

25 year power output warranty

Warranty

- Standard 25 year warranty on manufacturer defects and a 25 year power output warranty

Tests and Certificates

- IEC 61215, IEC 61730 Class C according to UL790

- IEC 61701 (maximum severity) Salt Spray Test

- IEC62716 Ammonia Test

- MIL-STD-810G Desert Test

- LeTID Test IEC 61215 (MQT 23.1 LeTID detection)

- Potential-induced degradation free: 1500V

- Listings: TUV Rheinland, CE

- ISO 9001:2008: ISO Quality Management System

- ISO 14001:2004: ISO Environment Management System

- OHSAS 18001: 2007 Occupational Health and Safety

Standard Equipment:

-

- Power Assurance Program For Linear Power Output.

-

- Produces more than 97.5% power in the first year and after 25 years 85.5%.

-

- Durability Test Cycle (accelerated Tests)

-

- 2000 hrs damp heat testing is twice the standard testing hrs. required

- 600 thermal cycling testing is three times the standard cycles required.

- 192 hrs of PID (potential-induced degradation) at 85°C/85RH) is twice the standard testing hrs. required.

- Mechanical Load testing for Dynamic + Thermal Cycle + Humidity Freeze result in much less cell breakage and power loss than static testing alone.

- 60-100 kWh/m2 LID (light-induced- degradation) validates early hour performance.

- LeTID (light and elevated temperature degradation) is a proprietary validation for long term PERC performance.

- Validated for use in harsh environment by IEC testing for salt mist, amonia, dust and sand.