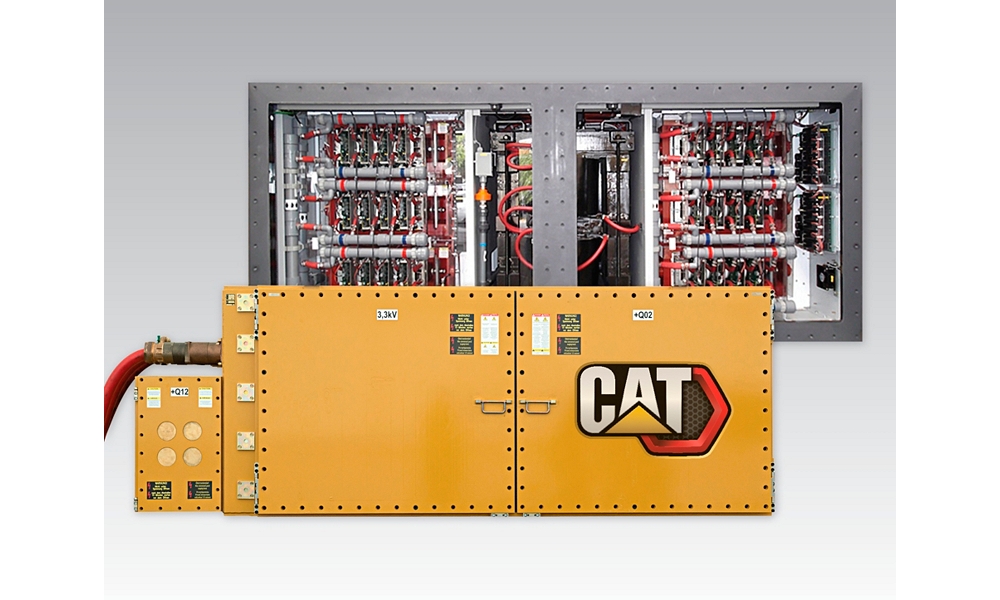

The Cat VFD-A800/W800 provides efficiency and maximized profitability for the motor control of armored face conveyors in underground longwall applications. The variable frequency drive consists of an air-cooled VFD unit, a liquid-cooled VFD unit, and an external cooling station. The Cat medium voltage drive delivers enhanced motor control and increased energy efficiency on motor applications with a rated power of up to 800 kW (1,072 hp).

| Technical Data | |

| Rated Power | 1072 hp |

| Input Voltage | 3300V ± 10% |

| Maximum Operational Torque | 210 % |

| Converter | Current Source Inverter (CSI) |

| Slew Rate | 20%-80% < 20 m/sec |

| Motor Type | AC motor |

| Output Frequency | 0-60 Hz |

| Input Frequency | 50/60 Hz ± 5% |

| Output Voltage | 0-3300V |

| Operation | 4Q |

| Power Factor (cos phi) | > 97.5% (PWM) |

| Setup | VFD separate from motor (cable distance up to 4 km/2.5 miles) |

| Dimensions (Approximate) | |

| Length | 146 in |

| Weight - VFD-A800 - Air Cooled | 14771 lb |

| Width | 49 in |

| Height | 51 in |

| Weight - VFD-W800 - Water Cooled | 17196 lb |

Ultimate Control of Your Drive System

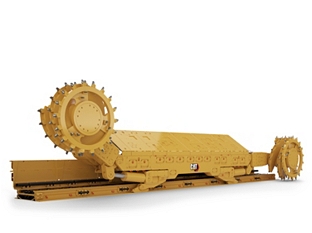

The Cat® variable frequency drive for face conveyor systems will supply exactly the power needed at your AFC or plow application - available with rated power of 800 and 1200 kW (1,072 and 1,609 hp). Cat VFDs simply make the most intelligent use of electrical power in longwall operations, yet. Optimizing the flow of material while saving on equipment life the Cat VFD is the accelerator for your productivity and return on investment while applying the brake on specific operating costs!

Simply Plug in Tomorrow's Drive Technology

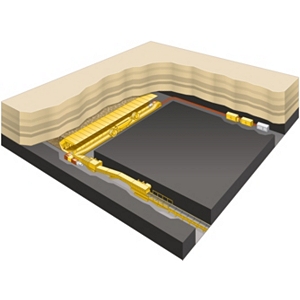

Cat medium voltage drives - consisting out of one air‐cooled and one liquid‐cooled unit ‐ are incorporated in a flame‐proof enclosure. Together with a dual circuit liquid cooling station the VFD containers can be positioned in the energy train at the gateroads of a longwall system. Cable distances to motors of up to 4 km (2.5 miles) are possible. The parameterization and control of the VFDs can be modified from the control system located on the surface. The Cat VFD drive does not require special motors. This medium voltage converter allows the use of standard AC motors and adopt to most existing systems providing you these benefits:

- No significant voltage drops during start‐ups so even “weaker” networks can increase their performance

- VFD separated from motor so that converter units can be installed up to 4 kilometers away from drives/motors saving space at the face entries

- VFD can be stacked in the energy train to meet whatever power demand your equipment may have

- 4Q‐operation uses motors to brake and regenerate power into the mains

Start up - Run - Share - Brake

The ever‐repeating cycles of AFC and plow chain drive operation are expertly mastered by the Cat VFD: Total torque at zero speed, maximum torque at start‐up, perfectly balanced torque at motors to share loads, motors braking the AFC (or plow) or stopping them immediately if overload situations occur. Infinitely controlling speed and torque through the alternating current's frequency makes the most efficient use of electrical power while keeping stress levels for the equipment and especially the chains at a minimum.

Precise Performance through Effective Power Structure

The Cat VFDs are utilizing a Pulse Width Modulated (PWM) Current Source Inverter (CSI). Converters of this type possess an effective power structure with a current limiting DC link inductor. The CSI VFD provides a near sinusoidal current and voltage waveform with total harmonic distortion (THD) below 5%. This reduces stress on the motor winding insulation.

Make electric power your production's brainwaves

Since VFD operation is all electrical and non‐mechanical, system parameters can be analyzed and adjusted in no time and with highest precision: data on torque, power, speed, and resolution/rpm are instantly available. So, adjusting the AFC's speed to the loading by plow or shearer is an instant operation that can match the longwall's overall output to outbye systems like the crusher or belt conveyor.