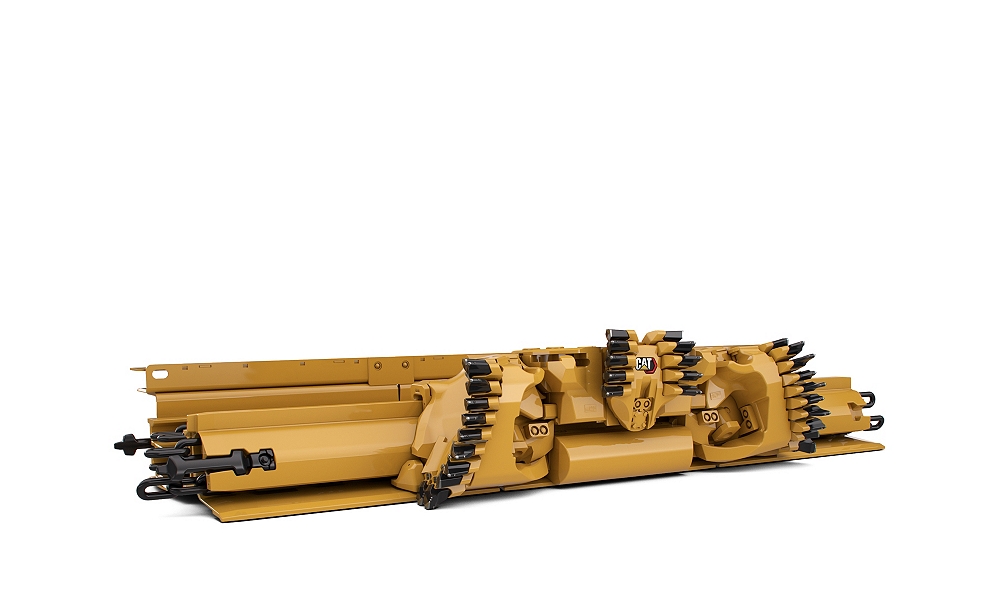

The Cat® GH800 Plow System, previously known as the GH 9-38 ve system, has been the standard plow of choice since the early 1990s and is used in seams from approximately 0.9 m (35 in) up to 2.0 m (79 in), regardless of the inclination of the seam or the hardness of the coal. Caterpillar modified this already-successful plow model to create the new technologically advanced GH800B plow, with improved design features enhancing productivity in minimum seam heights below 1.0 m (39 in). The plow body of this next-generation machine has an optimized design that allows it to load more coal onto the face conveyor and reduces the amount of cutting power wasted in the process. The GH800B plow system with 2 × 400 kW (2 × 536 hp) installed power now covers mining heights from 750 to 1550 mm (30 to 61 in).

| Specifications | |

| Coal Hardness | Soft-hard Coal |

| Maximum Installed Power | 2 × 400 kW (2 × 536 hp) |

| Maximum Cutting Depth | 0.67 ft |

| Mining Height | |

| Seam Range | 0.8 m-2.0 m (31.5 in-79 in) |

| Coal Hardness | |

| Type of Coal | Soft-hard Coal |

| Technical Data | |

| Bottom Bit Positions - Position 3 | –22 mm (–0.07 ft) |

| Plow Length | 8.65 ft |

| Bottom Bit Positions - Position 4 | –39 mm (–0.13 ft) |

| Bottom Bit Positions - Position 2 | –9 mm (–0.03 ft) |

| Coal Hardness | Soft-hard coal |

| Plow Heights - Height 2 | 1000-1285 mm (3.28-4.22 ft) |

| Plow Heights - With Gobside Support - Height 1 | 1535-1700 mm (5.04-5.58 ft) |

| Maximum Seam Inclination | 60° |

| Plow Heights - With Gobside Support - Height 2 | 1685-1965 mm (5.53-6.45 ft) |

| Mechanical Height Adjustment | 180-280 mm (0.59-0.92 ft) |

| Maximum Plow Speed | 600 ft/min |

| Plow Heights - Height 3 | 1270-1550 mm (4.17-5.09 ft) |

| Plow Heights - Height 1 | 750-1030 mm (2.64-3.38 ft) |

| Weight - Single Plow | 4385-5625 kg (10,660-12,401 lb) |

| Cutting Depth | 0.67 ft |

| Maximum Drive Power | 2 × 400 kW (2 × 536 hp) |

| Bottom Bit Positions - Position 1 | +19 mm (+0.06 ft) |

| Power | |

| Maximum Installed Power | 2 × 400 kW (2 × 536 hp) |

| Maximum Plow Speed | 600 ft/min |

The Principle of Plowing

We have been designing and building longwall plows since 1941 – and things have come a long way. Technical advances have once again established plowing as the preferred longwall mining method for seams below 1.8 m (70 in). Cat plows offer world-leading features that other manufacturers cannot, as well as a cost of ownership that far outstrips the shearer when mining thin and medium seams. Their reliability, high productivity and ability to mine in-seam make them the ideal choice for longwall mining medium and thin seams.

World-leading Features

Cat plows like the GH800B and GH1600 Gliding Plow Systems offer world-leading features that other manufacturers cannot offer – and a cost per ton that far outstrips shearer performance in thin and medium seams, making them reliable, high-productivity longwall mining systems.

How It Works

The plowing principle is simple: A sculpted steel plow body equipped with strategically placed cutting bits is pulled along the face conveyor from one end of the face to the other by a continuous loop chain powered by drives located at the face ends. Cutting depth is electronically controlled by pushing the AFC toward the face in preselected increments after the plow has passed.

Height-adjustable

The height of the plow body is easily and completely adjustable within a certain range, ensuring that only coal is cut. The plow body height can also be adjusted in larger increments by installing or removing additional bit blocks. Both adjustments can be performed quickly and easily from the gob side.

Remote Control

No operator is required at the face itself. Operation can be controlled from a central control station either underground – for example, at the head gate entry – or on the surface, so operators can work remotely in a dirt- and dust-free area. The outrigger steering system provides vertical horizon control. Steering is normally controlled manually, but can be automated. Shields are positioned to suit the longwall's geology and normally advance automatically with the cutting action of the plow.

System of Choice

The removal rate achieved by plows compared to shearers has continued to increase over the years. For seams with an average height under 1.8 m (70 in), plows are now the system of choice for longwall mining. In seams from 1.8 to 2.3 m (70 to 90.5 in), the choice of plow or shearer depends on the specific geological conditions.

Plow Body

The lower the coal seam the more difficult it is to mine, so loading the coal onto the Armored Face Conveyor (AFC) becomes ever more important in lower seams. The plow body of the Cat GH800B has an optimized design that allows it to load more coal onto the face conveyor and reduces the amount of cutting power wasted in the process. The new shape at both ends of the plow body and the lower height of the plow guide significantly improve the coal loading process in low seam heights.

Height-adjustment

The modular design allows the height of the plow body to be adjusted by simply inserting or removing bit blocks with a height of 265 mm (10 in) each. The plow body can also be adapted to smaller variations in seam height through an infinite height adjustment by means of a bit turret built into the plow body. The turret carries the top bits of the plow and can be precisely raised or lowered up to 300 mm (12 in) by means of a worm gear accessible from the gob side.

Shock Absorber (optional)

Caterpillar has developed an innovative shock absorber to provide added protection for the plow and chain. The elastic coupling inserted into the plow-pulling sledge contains elastomers with properties that reduce the peak forces applied to the chain. This results in smoother plow operation and minimized loads on the plow chain, the plow connectors and the drives, thereby extending their effective service life.

Benefits of a Shock Absorber

- Reduces wear and tear on plow, drives and chain

- Smooth plow operation extends overall service life

Plow Guide

The plow guide of the GH800B – which connects the plow body to the conveyor – is made out of a one-piece casting. This provides extra strength and durability while being much lower in height than the old welded plow guide. The casted plow guide can withstand the high reaction forces on the line pans from the powerful AFC drives. The plow guide is designed to generate minimum friction between the plow guide and plow chain. Doors inside the plow guide (at every second pan) can be opened for quick and easy access to both the top and bottom chain. Both gob-side and face-side pan connectors have a breaking strength of 3600 kN (404 tf) with the special PF3 or PF4 plow line pan modified for the use with this plow system.

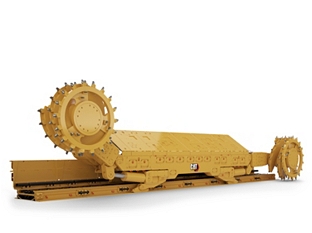

Plow Line Pans

One feature maintained by the new GH800B plow system is the Cat AFCPF3 or AFCPF4 conveyor, which uses plow line pans with a replaceable top trough for easy replacement of worn-out parts. They also feature external dogbone connectors between the line pans – each with a breaking strength of up to 3600 kN (404 tf), as well as a very strong and flexible relay bar between the conveyor and the roof supports. Inspection doors in every second line pan enable quick and easy access to both the top and bottom chains for maintenance. Furthermore, a widened conveyor cross-section with extended side plates increases the coal throughput. The GH800B allows higher production rates in low seams, depending on the geological conditions and other parameters.

State-of-the-art Conveyor Technology

The innovative Cat PF plow line pans are the state of the art for underground face conveyor technology. They are based on the tried-and-tested PF3 and PF4 pans, which meet all requirements regarding quality, wear resistance and conveying capacity. PF line pans form the powerful backbone of the conveyor system. This pioneering conveyor technology and extremely rugged pan design have been subjected to extensive testing.

Separation of Wear Parts

The smart and totally new idea of splitting up the different functional areas in the PF allows the separation of wear parts from structural parts. Very hard, wear-resistant materials are used for parts subject to wear, while the structural parts are made of tough, high-strength steels. The pan design allows problem-free replacement of worn-out top troughs.

Benefits of Separation of Wear Parts

- Substantially longer service life

- Considerably lower overall pan wear

- Easy underground replacement of wear parts

Optimized Contact Surfaces

The use of the proven PF profile in the top race maximizes the contact surface between the flight bar and the profile. This minimizes the flight bar surface pressure in snakes and undulating seams. Special shaping of the bottom race – which almost doubles the contact surface – substantially reduces both friction and wear of the flight bar shoulder. Also, the curved transition at the pan ends greatly reduces noise during operation of the chain conveyor.

Benefits of Optimized Contact Surfaces

- Minimal friction

- Low wear of flight bar shoulder in the bottom race

- Minimized power losses

- Longer service life of flight bars and profiles

- Lower noise level during operation

Plow Roof Supports

Low-seam Roof Supports

Roof supports for plow systems working in thin seams have special requirements and restrictions:

- Direct-acting DA ram allows the use of shorter roof supports to cope with undulating seams.

- Only high-strength steel is used for structural components to ensure minimum thickness and maximum travelway height.

- A split base allows the vertical movement of the relay bar necessary for effective horizon control and access to the DA ram for maintenance.

- Elephant step is available to prevent dirt accumulation and overcome soft floor conditions.

The low-seam roof supports of a GH800B plow system are specially designed for one application. They are available with shortened canopies to avoid a collision with the plow even in their lowest position. Furthermore, these shield canopies are not only shorter but also 8 cm (3.15 in) thinner to create a more ergonomic working environment for the face crew. A canopy water spray sequence –synchronized with the motion of the plow – keeps dust levels in this confined environment at a safe and healthy level.

Drive System

A plow body has no internal drive, so the GH800B plow is pulled along the coal face by an endless chain assembly powered by drive motors located at the face ends. The 38 mm (1.5 in) plow chain allows installations of up to 2 × 400 kW (2 × 536 hp).

Overload Protection

Effective overload protection is essential for fast, high-power plowing. The Cat planetary UEL gearbox overload protection system has an integrated multi-disc clutch with the pressure set to allow the clutch to slip well below the torque required to reach the breaking strength of the chain. If “clutch slip” is sensed, the gearbox torque is decreased immediately and the plow motors shut down to prevent damage to the chain. The Cat overload protection system:

- Eliminates shock loads from all drive components.

- Minimizes chain failures and maximizes component life.

- Allows for a quick system restart.

Load-sharing

Motors with Cat Variable Frequency Drives (VFD) – like the Cat VFD-A800/W800 – allow speed to be varied between 0 and 120% of nominal while maintaining constant torque throughout a wide range of speeds. Power consumption on the motors is constantly monitored to allow load-sharing between the individual drives.

Benefits of Load-sharing

- Full utilization of available power

- Prevention of motor overheating and resultant downtime

- Reduced motor current with optimal torque during startup

- Excellent power factor (~1)

Control System

Remote Control

Cat plow systems offer the Industry's most advanced remote control system. When running a GH800B plow system, there is no need for an operator at the face. The Cat MCU2 main control unit can control the entire longwall from a comfortable room underground or even from miles away on the surface. It visualizes face operations on a graphic display, including actual coal load on the AFC, shield position, leg pressure, stroke and plow position. The MCU2 provides a face-wide network and allows remote maintenance of shield components, as well as data recording and transfer of data to the surface.

PMC-D Drive Control

As the plow has no moving parts, plow control comes from a separate PMC-D drive control. The unit is typically dedicated to a gearbox or drive, and is mounted close to the device or application it controls. The PMC-D unit has all the hardware required to effectively control the many functions of a typical drive system. The PMC-D also determines the plow's position precisely and reliably by measuring drive chain travel. The PMC-D is typically used in conjunction with a PMC-V, which provides the human-machine interface (HMI) and visualization.

PMC-V (Visualization and Control Unit)

The PMC-V provides an operator interface to all installed PMC-D system units. It allows the operator to set parameters, and to store and view system data. The PMC-V has 24 keys for easy operation and includes a 4" VGA display for data visualization. Graphic trending and any warnings and error messages can also be clearly displayed. With a choice of interface languages, the PMC-V display shows all data available from the gearboxes – including transducer values, status information, global and local parameters, and network status. The VPlow software visualizes the entire plow system, from plow movements and progress to all parameter settings – especially of the overload-protected drive control.

Horizon Control

Effective plow horizon control is necessary to cope with undulations in the coal seam. Following the coal seam minimizes cutting of adjacent rock strata and the associated preparation costs, reduces cutting tool consumption, and reduces power consumption while maximizing seam recovery. Caterpillar has developed an outrigger steering system for vertical horizon control with hydraulic cylinders between the gob side of the AFC and the roof support's relay bar. Extending the cylinder promotes a downward (digging) cutting direction of the plow, retracting promotes an upward (climbing) direction. The steering cylinders can be controlled either manually or automatically via the Cat PMC-R electro-hydraulic control system. A block anchorage system consisting of cylinders installed between face conveyor and roof support at the face ends controls conveyor creep and helps maintain the correct plow chain tension.

Benefits of Horizon Control

- The plow advances in relatively small increments compared to a shearer. This allows the horizon control system to vertically steer the plow, keeping it in the seam even where seam undulations are severe. A shearer can only make gradual changes in vertical alignment, resulting in higher “out-of-seam” dilution in severely undulating conditions.

- Easy height adjustment allows plows to work smoothly through faults or undulations, minimizing the cutting of adjacent strata.

Incremental Plowing

The key requirements for high-performance plowing are remote control, adjustable cutting depth, and the ability to maintain a straight face line. These requirements are all achieved by the Cat incremental cutting system and the fully automated plow longwall system. With conventional plows, variations in coal hardness lead to variations in cutting depth that often result in overloading of the conveyor and downstream equipment or jamming of the plow. Incremental plowing prevents these problems by keeping the cutting depth constant regardless of coal hardness or presence of rock bands.

Benefits of Incremental Plowing

- Remote operation allows highest safety and maximum productivity in low coal.

- The AFC/plow system and roof supports can be positioned exactly where they are needed (snakes, roof condition, faults, etc.).

- System is self-correcting for over push and under push, keeping the face straight regardless of conditions.

- Optimal use of installed power for maximum cutting depth on every area of the face.

- Automated Cat plow systems allow access to extended reserves in low coal seams to achieve a higher percentage of reserve recovery.

- Significantly more coal can be mined with more efficient layouts, reducing overall costs.

Safety

Caterpillar is constantly improving our products in an effort to provide a safe work environment for all miners working underground.

- The Cat GH800B plow system is engineered to meet stringent safety standards while maximizing productivity in low coal. The operator is protected through remote operation and innovative control systems. No operator is required at the longwall face during operation itself. Operation can be controlled from a central control station either underground – for example, at the head gate entry – or on the surface, so operators can work remotely in a dirt- and dust-free area. Automated operation also improves face management due to constant monitoring and visualization, accurate and consistent documentation and analysis, as well as constant process improvement.

- Plow roof supports offer sophisticated dust suppression by ultra fine water mist. The plow system produces only minimum amount of fine coal (coal dust).

Serviceability

The plow body consists of mechanical components with all wear parts capable of being replaced underground. Any maintenance required during the mining process can be performed quickly and easily, as the plow is accessible anywhere along the face. Cat plow line pans can easily be maintained. The line pans follow a new concept of segregating the different functional areas – separating wear elements from structural elements. Extremely hard and wear-resistant materials are used for parts subject to wear, while the structural parts are made of tough, high-strength steels. The pan design allows problem-free replacement of worn-out top troughs, which delivers a lower cost of ownership during its lifetime. A plow system causes only minimum maintenance costs in lower seams – particularly compared to a shearer.