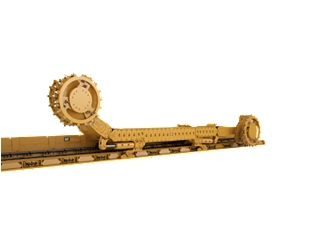

Moving Mountains – No matter how fast your shearer can cut, you can’t keep cutting until you move the coal away from the face. Cat® Armored Face Conveyors (AFCs) are designed to keep things moving and to carry the maximum possible amount of coal smoothly away from the coalface. They are designed for high availability and economy in operation. They are easy to maintain and offer long service life and a great return on investment to mine operators.

| Technical Data | |

| Dogbone Breaking Strength | 2000 kN (224.80 tonf) |

| Line Pan Width - PF3/722 | 28.42 in |

| Dogbone Housing FoS | 1.5 times |

| Profile Height | 9.6 in |

| Flightbar Width - PF3/722 | 22.91 in |

| Chain Strands | DKB 26×92; DKB 30×108; DKB 34×126; DKB 38×137 |

| Horizontal Articulation | 0.8°-1.2° |

| Shear Strength | 3000 kN (337.21 tonf) |

| Bottom Plate Thickness | 0.78 in |

| Line Pan Width - PF3/922 | 36.3 in |

| Vertical Articulation | up to ±6° |

| Flightbar Width - PF3/922 | 30.78 in |

| Line Pan Width - PF3/822 | 32.36 in |

| Deck Plate Thickness | 1.18 in |

| Conveying Capacity - PF3/922 | 3.87 ft² |

| Conveying Capacity - PF3/822 | 2.8 ft² |

| Conveying Capacity - PF3/722 | 1.93 ft² |

| Flightbar Width - PF3/822 | 26.85 in |

| Typical Technical Data AFC Line Pan | |

| Dogbone Breaking Force | 449618 lb |

| Top Plate Thickness | 30 mm (1.18 in) |

| Bottom Plate Thickness | 0.78 in |

Engineered to Perfection

Cat AFC components achieve this. Each is designed for powerful, reliable and economical operation with low maintenance over a long service life, promoting high productivity and delivering a great return on investment.

Shearer Haulage System

As with all Cat products, these systems are the result of extensive R&D work and comprehensive laboratory and field testing. This ensures the optimum solution for haulage system and sprocket. This led to a unique design concept with optimized first/last tooth geometry rackbars available with pitches of 126 mm for medium-production and 146/151 mm for high-production shearers.

Drive Frames

Benefits

• Head drive does not cause a production bottleneck, maximum stability at maximum power, high power drives can be installed, upgrade normally possible, high AFC performance and availability

Drive Modules

Benefits

• Drive module can be replaced underground without disassembly of the gearboxes, drive units are available in different sizes and are independent of the gearbox used

GR Sprocket

Benefits

• More efficient power transmission with GR sprocket (97% vs. 93%), resulting in extended sprocket and chain life and less chain stretch

Tail Drives

Benefits

• Maximum chain life and minimum conveyor downtime for double cut

Gearboxes

The UEL gearbox - a planetary gearbox with an integrated clutch - is designed for higher-power requirements. This friction clutch is closed through face support hydraulic fluid. A hydraulic control system allows the clutch to be set to a certain torque.

Overload Protection

Benefits

• Caterpillar has the right drive for your application ensuring smooth and safe operation of the conveyor with overload protection and a range of other safety features as required

Chains

The latest development is the Cat PowerChain. It is available in sizes 34, 42 and 52. Size 52 is designed to be used with up to 1200 kW (3 × 1,608 hp), with a chain suitable for up to 1800 kW (3 × 2,412 hp) under development.

PowerChain

Benefits

• Faster removal of mined coal by providing high-reliability, high-availability transportation with design features ensuring low wear and long service life, greater permissible elongation of chain compared to round link

Entry Conveyors and Belt Tailpieces

Benefits

• Stage loader and crusher completely matched to AFC, both with higher capacity to prevent bottlenecks; tailor-made belt tailpiece for required capacity and belt dimensions, allowing BTP to handle longitudinal and lateral entry gradients; automated chain tensioning system

Line Pans for Every Need

That's why Caterpillar has focused on rolled steel designs for line pans. All aspects of the line pans have been engineered with reliability, productivity and serviceability in mind.

Maximum Contact

Benefits

• Minimizes friction, reduces power requirements for the face conveyor and results in longer service life of the flights and profiles

Rolled Steel

Benefits

• Lower friction and longer service life for wear parts. Up to 10 million tonnes (11 million tons) under normal conditions and up to 20 million tonnes (22 million tons) under favorable conditions.

Safe Dogbone Technology

Benefits

• Longer service life of dogbone pockets, no damage to conveyor or dogbone housing as the dogbone always breaks first

Convex/Concave Pan Ends

Our line pans are suitable for bi-directional operation.

Welds without Wear

Benefits

• High stability of the pan ensured by three welds even when the top plate is totally worn out

Wear-resistant Top Plate

Benefits

• Long service life with matched profile type end

Flexibility

Benefits

• Increased flexibility, adaptation to undulating seams, short snake sections possible

Safe Transfer of Transverse Forces

Benefits

• High pan stability, even for high-reaction forces; safe operation; low noise; minimum maintenance; full reversibility

Inspection Doors

Benefits

• Easy access to bottom chain, minimum downtime during maintenance or repair