.

Description

Technical Specifications

Benefits and Features

Equipment

360 View

The PM822 is a high-production, half-lane milling machine with a cutting width of 2235 mm (88 in) that performs controlled full-depth removal of asphalt and concrete pavements in a single pass.

| Cutting System | |

| Milling Width | 88 in |

| Maximum Milling Depth | 13 in |

| Rotor Speeds | 100 / 109 / 118 rpm |

| Number of Bits | 193 |

| Power Train | |

| Rated Power | 806 hp |

| Engine | Cat C18 twin-turbo |

| Maximum Travel Speed | 3.7 mile/h |

| Maximum Milling Speed | 328 ft/min |

| Weights | |

| Operating Weight | 80910 lb |

| Transport Weight | 72312 lb |

| Dimensions | |

| Operating Length - Conveyor Up | 47.64 ft |

| Operating Width | 10.2 ft |

| Height - Canopy | 13.29 ft |

| Maximum Truck Clearance | 15.94 ft |

| Minimum Right Cutting Radius | 5.91 ft |

| Minimum Left Cutting Radius | 6.56 ft |

| Conveyor Swing | 60 degrees from center |

| Transport Length | 40.78 ft |

| Transport Width | 8.99 ft |

| Transport Height | 9.84 ft |

| Service Refill Capacities | |

| Cooling System | 27.5 gal (US) |

| Engine Oil | 17.2 gal (US) |

| Fuel Tank | 292.7 gal (US) |

| Hydraulic Tank | 29.9 gal (US) |

| Water Spray System Tank | 898.2 gal (US) |

Efficient Performance

- Powerful Cat® C18 twin-turbo engine meets regional emission standards

- Smooth and efficient operation with Automatic Idle Control and multiple rotor speeds optimize output and demand on the engine

- High capacity cooling system keeps engine at ideal temperatures for optimal fuel efficiency and lower emissions

- Automatic load sensing on the rotor adjusts milling speed to prevent stalls and optimize production

Maneuverability and Control

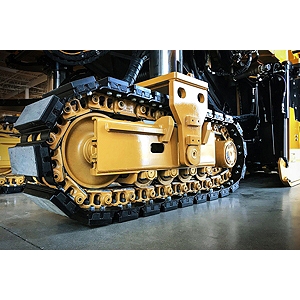

- Reliable track undercarriage leverages proven designs from Cat dozers and an automatic tensioning system to ensure consistent performance and longer track life

- Robust propel system features two independent propel pumps to drive two crawler tracks each, in a high-traction, cross-drive pattern

- Automatic traction control maintains consistent speed in the most challenging applications

- Four steering modes with advanced alignment and tracking provides precise steering geometry and reduces track pad wear

- Ability to electronically switch between rotor speeds during operation

Material Removal

- High-capacity conveyors provide efficient removal of milled material with outstanding discharge control

- A wide opening and seamless belt effectively clear the rotor chamber

- Adjust the belt speed to match material type and production rate, while the built in “boost” feature provides a temporary surge in belt speed to eject material faster and farther

- The belt reverses for faster clean-up, while magnetic vinyl covers provide quick access to inspect the rollers for wear

Comfortable Work Environment

- Operate in comfort with height-adjustable operating consoles and intuitive, ergonomic controls

- Retractable handrails stow and redeploy easily when approaching obstacles

- Work day or night with backlit keypads and illuminate the work area around the machine with wide-dispersion and perimeter LED lighting options

- Upgrade operator stations with optional suspension seats that reposition for improved visibility and comfort

- Optional remote cameras enhance visibility to the cutting edge and conveyor

- The single post, forward-folding powered canopy option with overhead LED lighting and integrated side extensions quickly stows and redeploys during operation to clear overhead obstacles with the simple push of a button, and optional windscreens can be added for increased comfort

- Maximize dust removal from the working areas with the optional dust abatement system

Durable Cutting System

- The rotor drive system features a heavy-duty dry clutch, automatic belt-tensioning to prevent slippage and two high tensile (five-rib) belts to drive the rotor

- Reinforced cutting chamber offers enhanced durability

- Improved access simplifies rotor changes

- Hardened full length side plate skis, inboard ski shoe, and anti-slab shoes reduce wear and maintenance

Boost Precision with Integrated Technology

- Achieve accurate, repeatable and automatic cutting precision with the integrated Cat GRADE with Grade and Slope system

- Control boxes can be repositioned without the need to reconfigure settings and the background color changes to night mode when the work lights are activated

- Obtain full control of grade and slope from any control box

- Seamlessly switch between multiple grade sensors for uninterrupted accuracy during milling

- Adjust the speed at which the rotor drops into the cut for optimal machine control

- Set and automate transitions in/out of cuts and save settings for future jobs

- Clear obstacles in the cutting path with ease using the obstacle jump feature

- Enhance for full 3D milling operation (additional hardware required)

System K Rotors

- Cat System K rotors feature efficient material flow with an excellent cutting pattern for numerous applications

- A tapered dual-retention design secures toolholders in place without a retaining pin, bolt or setscrew, speeding up replacement and eliminating the need for fasteners or torqueing

- Reversible paddles and high strength alloys reduce wear and abrasion to extend rotor life

- Optional diamond bits can extend replacement intervals up to 80 times longer than conventional carbide bits

Simplified Service

- Maintenance is easier and faster with large service doors and power hood for walk-in access to critical components

- Maintenance-free track components and easy to replace track pads lower service costs

- Standard ground-level controls and an optional electrically-operated rotor turning device with pendant simplify bit removal and replacement

- High and low pressure washdown options connect to the onboard water tank for convenient clean-up

- Operate select machine functions during maintenance and service with the accessory drive system

- Electrical system wiring is color-coded and numbered for easy identification and wrapped in a protective, abrasion-resistant nylon braid for longer life

- Extended hydraulic oil service intervals: 3000 hours without oil sampling, 6000 hours with oil sampling

- Track scheduled maintenance with Cat Product Link™ telematics services

- Electronic Control Modules (ECMs) monitor machine systems to alert the operator of performance issues and can be paired with Product Link options to enable additional remote services with your local Cat dealer

- Multi-piece, cartridge-style engine filters are environmentally friendly, reducing waste and lowering replacement costs

- Convenient parts availability, dealer locations and service repair kits simplify ordering of high wear components

Convenience Features

Cat cold planers offer a variety of features and options designed to make daily operation and maintenance tasks easier.

- Pause and resume machine functions with the push of a button during truck exchanges

- Optional magnetic paint can holders

- Hooks for water hose storage

- Angled water fill connection

- Easily accessible shovel holder

- Top and side view rotor depth indicators

- Compressed air connection in center operator console

Sustainability

- The Cat C18 Twin Turbo engine meets U.S. EPA Tier 4 Final and EU Stage V emission standards.

- Cat U.S. EPA Tier 4 Final and EU Stage V diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester) or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

- Automatic Idle Control helps reduce unnecessary fuel burn and greenhouse gas emissions by allowing the engine to automatically go into idle mode when the machine is not working.

- Automatic Load Control helps you save fuel and reduces greenhouse gas emissions by automatically matching milling speed to engine load for maximum production at peak efficiency.

- Standby/Resume pauses major machine functions and lowers engine speed to conserve fuel and helps reduce greenhouse gas emissions during truck exchanges.

- Traction Control maintains consistent traction to increase machine efficiency, helps reduce fuel burn and greenhouse gas emissions.

- The engine, fuel and hydraulic systems are equipped with ecology drains for easy servicing and to help prevent spillage.

- Extended maintenance intervals not only reduce downtime but decrease the amount of fluid and filters that are replaced over the life of the machine: hydraulic oil 6000 hours with sampling, coolant 12000 hours with extender.

- Cat Scheduled Oil Sampling (S•O•S℠) Services helps reveal excessive wear, contaminated fluids or other “unseen” issues that can shorten component life. In many cases, you can extend oil and coolant change intervals by using fluid monitoring. Consult your Cat dealer or the machine’s operation and maintenance manual for more information.

- Cat Grade with Grade and Slope for cold planers allows for accurate material planning to help reduce overages during the paving process and increase final project quality for a longer lasting road surface.

- Don’t waste fuel idling. Cat VisionLink® online fleet monitoring helps you manage idle time and reduce fuel burn and greenhouse gas emissions.

- VisionLink displays the CO2 emissions for monitored assets, calculated by fuel type for the Runtime Fuel Burned each day in a selected date range.

Standard Equipment:

-

- Operator Environment

-

- Ground control keypads

- Single high-resolution LCD touchscreen display

- 12-volt power receptacle

-

- Cat Connect Technology

-

- Cat Product Link

- Cat GRADE

-

- Conveyor

-

- Grease tensioner

- Material removal boost feature

-

- Rotor System

-

- Automatic plunge-cut

- Automatic transition feature

- Obstacle jump

- Three cutting speeds

-

- Powertrain

-

- Auto engine idle control

- High capacity cooling system

- Dual propel pumps

- Automatic load control

-

- Hydraulic System

-

- Dual pump hydraulic propel system

- Traction control

-

- Service And Maintenance

-

- Sampling ports for Scheduled Oil Sampling (S·O·S℠)

- Power hood

- Platform-level engine oil dipsticks

- Rotor chamber water spray system

- Air compressor

- Accessory drive system

- 3400 L (898 gal) onboard water tank

- Side water fill valve

-

- Safety And Security

-

- Platform handrails

- Signaling/warning horn

- Wide-dispersion LED work lights

Optional Equipment:

-

- Operator Environment

-

- Dual high-resolution LCD touchscreen displays

- Hydraulically folding canopy with LEDs

- Air-ride suspension seats

- Windscreens

-

- Cat Connect Technology

-

- Inboard ski

- Sonic sensor (averaging or string line)

- Ground level grade controls and displays

-

- Conveyor

-

- Dust abatement system

- Remote camera (loading conveyor)

-

- Rotor System

-

- System K Rotor - Course (25 mm)

- System K Rotor - Course (18 mm)

- System K Rotor - Standard (15 mm)

- System K Rotor - Fine (8 mm)

- System K Rotor - Micro (6 mm)

- System H Rotor - Micro (6x2 mm)

- Diamond bits

- Bit bucket trays

- Pneumatic bit removal tool

- Tool holder extractor

- Rotor turning device with pendant control

-

- Powertrain

-

- CE certificate

-

- Hydraulic System

-

- Water tank transfer pump

- Fuel transfer pump

-

- Service And Maintenance

-

- High pressure washdown

- Low pressure washdown

- Additional spray bars

-

- Safety And Security

-

- Perimeter LED strip lights

- Magnetic LED work light

- Warning beacon (fixed or magnetic mount)

- Truck signal lights

- Remote camera (rear, front, magnetic mount)