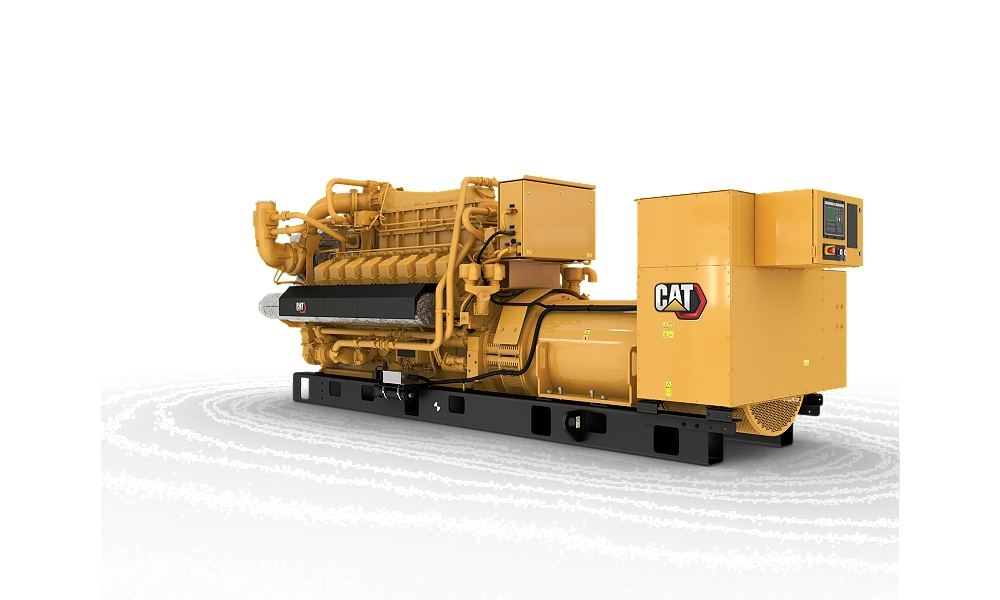

G3516C Generator Set

| Generator Set Specifications | |

| Continuous Rating | 1660 ekW |

| Fuel Type | Natural Gas |

| Maximum Electrical Efficiency | 37.70% |

| Maximum Standby Rating | 1500 |

| Frequency | 50 / 60 Hz |

| RPM | 1500/1800 |

| Engine Specifications | |

| Engine Model | G3516C |

| Displacement | 4210 in³ |

| Aspiration | TA |

| Bore | 6.7 in |

| Stroke | 7.5 in |

| Generator Set Dimensions | |

| Length | 219 in |

| Width | 72 in |

| Height | 92 in |

| Dry Weight - Genset | 31226 lb |

Cat G3516C Gas Engine

- Robust high speed block design provides prolonged life and lower owning operationg costs

- Designed for maximum performance on low pressure pipeline natural gas

- Simple open chamber combustion system for reliability and fuel flexibility

- Leading edge technology in ignition system and air/fuel ratio control for lower emission and engine efficiency

- One electronic control module handles all engine functions: ignition, governing, air/fuel ratio control and engine protection

SR4B Generator

- Designed to match performance and output characteristics of Caterpillar gas engines

- Industry leading mechanical and electrical design

- High efficiency

EMCP 4.3 Control Panel

- User-friendly interface and navigation

- Scalable system to meet a wide range of installation requirement

- Expansion modules and site-specific programming for specific customer requirements

Emissions

- Meets most worldwide emissions requirements down to 0.5 g/bhp-hr NOx level without aftertreatment

Proven System

- Field proven in a wide range of applications worldwide

- Fully prototype tested

- Certified torsional vibration analysis available

Full Range of Attachments

- Wide range of bolt-on system expansion attachments

- Factory designed and tested

- Flexible packaging options for easy and cost effective installation

Worldwide Product Support

- Cat dealers have over 1,800 dealer branch stores operating in 200 countries

- Your local Cat dealer provides extensive post-sale support, including maintenance and repair agreements

Standard Equipment:

-

- Air Inlet

-

- Two-element single-stage air cleaner with enclosure and service indicator

-

- Control Panels

-

- EMCP 4.3

-

- Cooling

-

- Jacket water and SCAC driven pumps and bypass lines

- 2nd Stage SCAC-Cat Flange

- Engine driven water pumps for jacket water and aftercooler

- Jacket water and SCAC thermostats

- ANSI/DN customer flange connections for JW inlet and outlet

- Cat flanges on SCAC circuit

-

- Exhaust

-

- Integrated Sensing Module (ISM)

- Cat-flanged face outlet on turbocharger

- Provides exhaust port temperatures and stack temperature to customer supplied screen via CCM

- Dry exhaust manifolds, insulated and shielded

-

- Fuel System

-

- 24V ETR Gas Shutoff Valve

- Engine installed, fuel metering valve

- Throttle plate, 24V DC actuator, controlled by ECM

- Fuel system is sized for 31.5 to 47.2 MJ/NM3 dry pipeline natural gas with pressure of 10.2 to 34.5KPa to the engine fuel control valve

- Fuel Filter

-

- Ignition System

-

- Individual Cylinder Detonation Sensitive Timing (DST)

- Electronic Ignition System (controlled by ECM)

-

- Fuel System

-

- Electronic fuel metering valve

-

- Generator

-

- Anti-condensation space heater

- Busbar connections

- Class H Insulation & Class F temperature rise

- Reactive Droop

- Permanent Magnet Excitation

- 3-phase brushless, salient pole

- Caterpillar's Digital Voltage Regulator (CDVR) with 3-phase sensing and KVAR/PF control

- SR4B

- Winding temperature detectors

-

- General

-

- RH Service

- Operation and maintenance manuals

- Crankshaft Vibration Damper and Guard

- Parts Book

-

- Starting/charging

-

- 24V starting motors

Optional Equipment:

-

- Air Inlet

-

- Vertical, horizontal dual element air cleaner

- Enclosure mounting brackets and piping

- Air cleaner with precleaner

-

- Control Panel

-

- Local NFPA99-110 Alarm Module w/LEDs

- Synchronizing Module

- Remote 24V 8/16 Light Annunciator

- Engine Failure Relay

- PL1000E/PL1000T Communications Module

- Custom 8-Light Alarm Module

-

- Cooling

-

- Inlet/Outlet connections

- Jacket water coolant heater

- Aftercooler air lines, aftercooler core replacement

-

- Exhaust

-

- Flexible Fittings

- 14" Flange Kit

- 406 mm Elbow Kits

- 406 mm flange kits

- Mufflers (15/18/25 dBA Attenuation) and spark-arresting muffler with ANSI companion flanges

- 16" Spark Arresting Muffler

- 356-406mm Flange and Exhaust Expander

- 15/18/25 dBA Muffler Attenuation

-

- Fuel System

-

- 207-276kPa, 30-40 psi gas knockdown regulator

- 14-69 kPa (2-10 psi) gas pressure regulator

- 24VDC Gas Shutoff Valve, Gas Knockdown Regulator

- Fuel Filter, Gas Filter

-

- Generator

-

- Cable access box

- 8.7/15 kV Cross, Differential, Current Transformers (CCCT, DCT, CT)

- Medium and high voltage generators and attachment

- 480/4160/13200 Volt Generator Options (60 Hz)

- Generator air filter

- Bearing temperature detectors

- European Bus Bars

- 415/400/380, 3300/6600/11000 Volt Generator Options (50 Hz)

- Annunciator Modules

- Generator Removal

- Low voltage extension box

-

- Governing System

-

- Load share module

-

- General

-

- Special paint order

- Tool set

- US AID Emblem

- Barring group

- Digital diagnostic tool

-

- Starting/charging

-

- 60A, 24V charging alternator (requires engine driven pumps)

- Battery removal

- 20A battery charger

- Battery disconnect switch

- Battery with cables and rack (shipped loose)