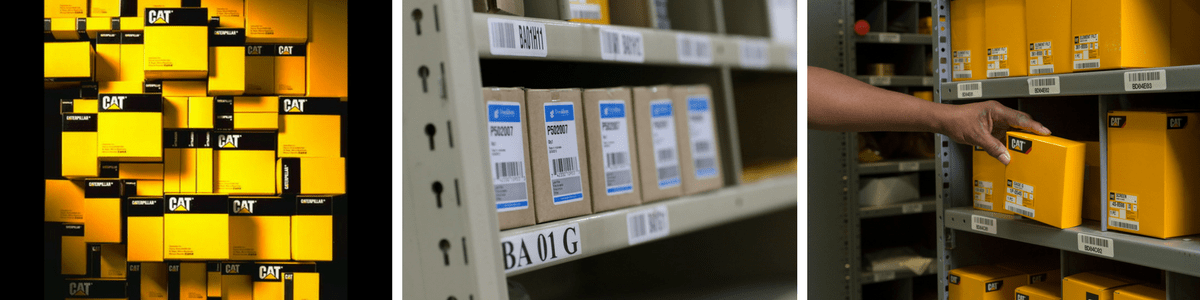

Genuine Cat Parts

At NMC we know when you need parts, you need quality options and you need them fast. We have genuine Cat parts, remanufactured (reman) parts, exchange parts, and used parts available online with quick ordering. From fluids and filters to complete components such as engines, transmissions and torque converters, NMC Cat has what you need.

Air Filters

One way contamination enters engines is in the air, and today’s tight engine tolerances require the cleanest air possible. With Cat air filters, you have more choices than ever for cleaning the air that enters your engine.

Standard Radial Seal Filters

Inadequate air filtration can reduce horsepower, rob performance, and ultimately damage your engine. Cat air filters feature a radial seal design that provides a better seal and easier servicing than conventional axial seal air filters. By preventing dirt, soot, sand, and other contaminants from entering your system, Cat Standard Radial Seal Filters help you lower maintenance costs and service time.

Ultra High Efficiency Radial Seal Filters

These filters are designed for environments filled with fine dust, soot, or both. Cat Ultra High Efficiency Radial Seal Filters can last two to four times longer in these conditions than standard filters.

Turbine Precleaners

This air intake system ejects particles, allowing your air filter to work longer in environments with high amounts of airborne debris. Turbine PreCleaners can provide two to four times more air filter life in many applications. They also minimize air filtering service.

Air Filter Air Service Indicator

This easy-to-read indicator shows the progression of air restriction caused by contaminant buildup in your filter element. The Air Filter Service Indicator lets you know at a glance the amount of filter life used – and how much filter life remains.

Drive Train Parts

Drive train components must endure incredible torque, high impact loads, and frequent direction and gear changes. Cat designs and manufactures its transmissions and final drive components with these demands in mind, using testing processes that simulate real world applications. The result is a drive train that lasts longer and works harder over the life of your machine. Learn more about drive train components below.

Transmission

The power coming from the engine must be turned into useful power by controlling its speed, direction and force. Transmissions do this using either hydraulically engaged planetary clutches or hydrostatic/hydraulic drives. Each of these methods provides different characteristics of ground speed, torque, clutches maneuverability, and implement force.

Because of the wide variety of work they do, Caterpillar products use several types of transmissions, each designed to convert engine power into the exact combination of speed and force required by individual machines.

Torque Converter

The power that is produced in the engine is multiplied in the torque converter and then transferred on to the transmission for use by the rest of the drive train components. Some Cat machines use a torque divider instead of the traditional torque converter, which divides the transmitted torque between the front and rear axles, with the rear receiving the majority. The three basic torque converter components include the impeller, the turbine, and the stator.

Drive Shaft

The drive shaft is a means of connecting drive train components. It allows for misalignment in the drive. The output shaft connects to the transmission through a yoke and drive shaft or directly to the transmission input gear.

Caterpillar’s exact design for proper measurements and precise machining ensures proper gear alignment. Special heat treatment achieves proper surface hardness, core hardness, and hardened depth.

Differential

The differential decreases the speed and increases the torque as needed for each wheel’s motion adjustment. When a machine is turning, the differential supplies the needed adjustments to the wheels, allowing the outside wheel to move at a faster pace than the inside wheel.

The components of the differential are the differential case assembly, the pinion gears, the side gears, and the spider. The differential’s key functions are:

- Transferring power coming from the transmission to the left and right axle shafts

- Balancing the power according to the demand of each wheel

- Further reducing the speed and increasing the torque to drive the rear wheels

Final Drive

The final drives are an important part of the drive train. They are the components that apply driving force to the wheels or tracks.

The final drives of a track-type tractor differ somewhat, but they perform the same function. They reduce rotating speed and increase torque. In fact, this is where the greatest torque rise occurs…in the gears. That allows these components ahead of the final drives to be smaller, which saves weight and space.

There are four types of final drives used in Caterpillar machines:

- Bull Gear Single Reduction

- Bull Gear Double Reduction

- Planetary Single Reduction

- Planetary Double Reduction

Brakes

Brakes are the components that slow, stop or hold a machine stationary. On Caterpillar machines, they are located at the wheels of wheel-type machines. In track-type machines, they are located on the axle shafts.

Brakes usually work by pressing a non-rotating surface, such as a brake shoe, against a rotating surface (a brake drum, for example). The resulting friction stops the machine. At this point where the two meet, the inertial force of the machine is sometimes converted into bake-oven heat.

The braking requirements of various types of machines differ, chiefly because of differences in the work they do. To assure each type of machine has the braking system that best suits its needs, Caterpillar uses four types: Expanding Shoe, Caliper Disc, Wet Disc and Expander Tube.

Engine In-Frame Overhaul Kits

NMC Cat is ready to help you extend the life of your engine. When you use Caterpillar parts, you can be assured of high-quality materials and controlled manufacturing processes. With our new in-frame overhaul kits, you have value-added options for overhauling your engine the right way, with the top performance and long life of genuine Cat parts. Read below to learn more about how our engine overhaul kits offer long life, quick turnaround time and an easy ordering process.

Precious Metals Overhaul Kits

Precious Metals In-frame Overhaul Kits are engineered to deliver a reliable and high-quality rebuild that meets Caterpillar’s recommended overhaul practices. They include all parts necessary for a variety of repair options, from a basic repair to a complete in-frame overhaul. Kits can be purchased over-the-counter at any NMC Cat Machinery Parts Department location and come with a factory-backed, one-year parts warranty that covers Cat parts needed to correct the failure, including Cat parts damaged by the failure and labor needed to correct the failure (when work is performed at NMC Cat or an authorized Cat dealer).

In addition to being engineered to deliver a reliable and high-quality rebuild, these self-contained kits offer improved pricing; pre-packaged, genuine Cat parts for your convenience; ease of ordering and handling; and minimized selection errors.

We’re Ready with OptionsWith four cost-effective and simple-to-order overhaul options, Precious Metals In-frame Overhaul Kits cover 3306 as well as most heavy-duty Cat engines with serial number prefixes, and come in four levels: Bronze, Silver, Gold, and Platinum. Each succeeding level offers more value.

- The BRONZE overhaul kit is your low-cost repair option and includes value-added components like Cat oil filters and fuel filters and components you might not think of replacing, such as exhaust sleeves and exhaust manifold studs. There is no core charge with the bronze overhaul kit.

- The SILVER overhaul kit is suitable for a basic in-frame overhaul and is similar to competitive in-frame overhaul kits. It builds on the Bronze overhaul kit and also has no core charge.

- The GOLD overhaul kit is suitable for a basic in-frame overhaul and includes the core parts from the Bronze kit and the added bonus of Cat Reman cylinder pack assemblies. Reman cylinder packs are beneficial because the rods, pistons, rings, and liners come preassembled, saving four to six hours of labor when compared to the Silver overhaul kit.

- The PLATINUM overhaul kit includes all the components from the Gold kit plus a Cat Reman cylinder head assembly, Cat Reman fuel injectors, a Cat Reman water pump, and a Cat Reman oil pump. The Platinum overhaul kit optimizes engine performance and fuel economy and maximizes the built-in second or third life of your engine.

Fuel Filters

In fuel systems, secondary filters capture particles as small as 2 microns. But how small is a micron? An average human hair is 80 microns in diameter. The smallest dust particle the human eye sees is typically 40 microns across. That’s the equivalent of 1/500 of an inch. Cat system clearances are from 2 to 30 microns. So it truly is the dirt you can’t see that you must guard against. Read on to learn how Cat fuel filters can help.

Stop Contamination Before it Stops You

Contaminants can be as abrasive as the materials used to machine parts in the manufacturing process, so it’s important to remove as many contaminants as possible before the fuel reaches critical components. Fuel system contaminants are known to cause premature injector wear, reduce component life, reduce performance and cause sudden injector seizure.

Abrasive contaminants of only 5-10 microns and larger can damage injectors by breaking down the fluid film between moving parts and eventually scratching injector plungers and barrels, causing metal-to-metal contact and injector seizure. As little as one spoonful of dirt in a tank of unfiltered fuel can ruin a fuel injector in less than eight hours.

Measuring Fuel Filter Performance

Fuel filter performance has traditionally been quantified through an industry multipass test that measures the number of particles upstream and downstream of the filter. However, this procedure uses test fluid instead of low sulfur fuel and doesn’t simulate real-world conditions such as operating temperature, vibration, and pump pulsations.

A new test, Wear Indexing, uses low sulfur fuel to measure filter performance more accurately. This test better reflects how fuel filters protect fuel injectors.

The Wear Index test shows the Cat High Efficiency Fuel Filter (1R-0749) significantly outperforms four competitive filters, providing the best injector protection.

Maximum Protection for Fuel Injectors

Higher pressures and closer tolerances make today’s fuel injectors, pumps and components more susceptible than ever to wear and damage from contaminants. Cat High Efficiency Fuel Filters fight fuel contamination more effectively than standard fuel filters. The critical component is a super-fine filtration media that removes more than 98 percent of particles 2 microns and larger. By comparison, standard filters only capture particles 15 microns and larger. Cat High Efficiency Fuel Filters offer:

- Maximum engine performance and fuel economy

- Reduced exposure to abrasives

- Reduced wear on injectors and pumps

- Fewer fuel system adjustments

- Easier starting

- Longer filter life

Batteries

Cat Premium High Output Batteries

Cat Premium High Output (PHO) batteries are standard equipment in all Caterpillar machines and engine generator sets. They are designed to meet stringent Caterpillar design specifications for vibration (5-times the industry standard), deep discharge, recharge, SAE J2185 life cycle, container strength, extreme temperature, high cold cranking amp (CCA), and amp-hour capabilities.

PHO batteries are available worldwide in popular BCI group sizes for both Cat machines and other brands. They include both maintenance-free and low-maintenance designs and are available in wet and dry configurations. Selected BCI group size batteries are offered for automotive, marine, recreational, on-highway truck, and bus applications.